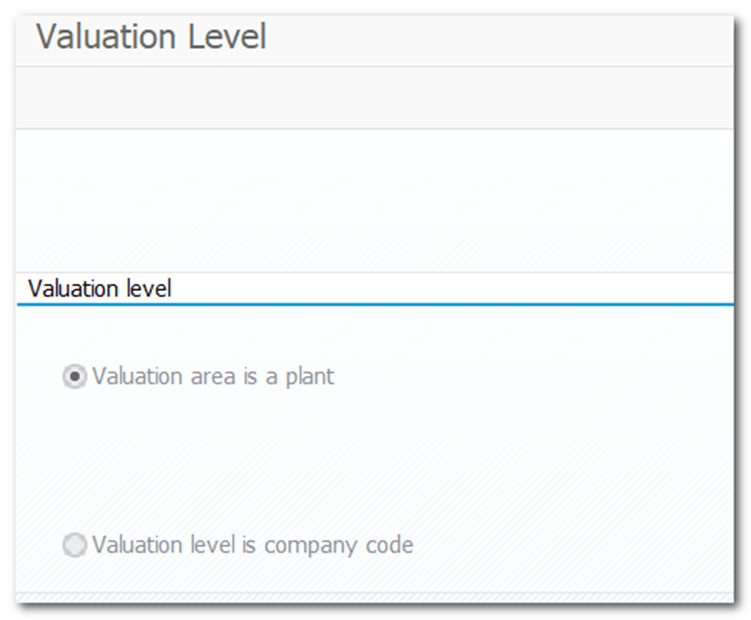

| Step 1 | Define Valuation Level (Plant or Company Code) |

| IMG | Enterprise Structure- Definition- Logistics – General- Define valuation level |

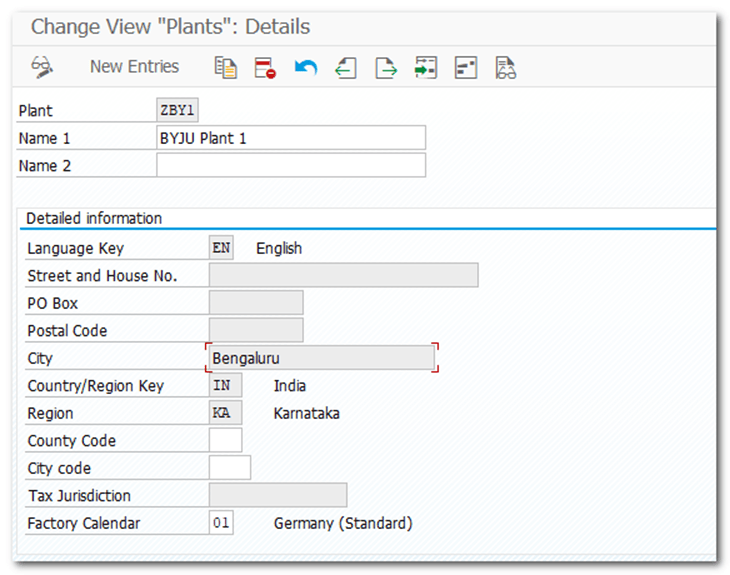

| Step 2 | Define Plant |

| IMG | Enterprise Structure-Definition-Logistics – General- Define, copy, delete, check plant |

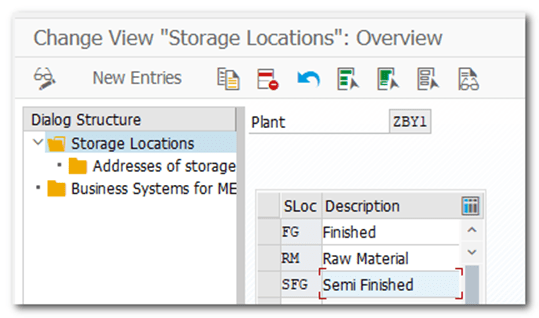

| Step 3 | Define Storage Location |

| IMG | Enterprise Structure-Definition- Materials Management- Maintain storage location |

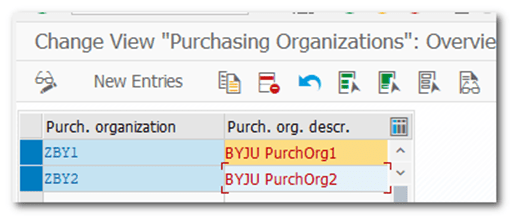

| Step 4 | Define Purchase Organization |

| IMG | Enterprise Structure-Definition- Materials Management- Maintain purchasing organization |

| Step 5 | Assign plant to company code |

| IMG | Enterprise Structure- Assignment- Logistics – General- Assign plant to company code |

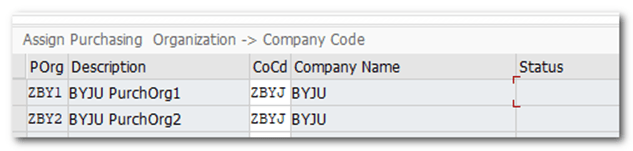

| Step 6 | Assign purchasing organization to company code |

| IMG | Enterprise Structure- Assignment- Materials Management- Assign purchasing organization to company code |

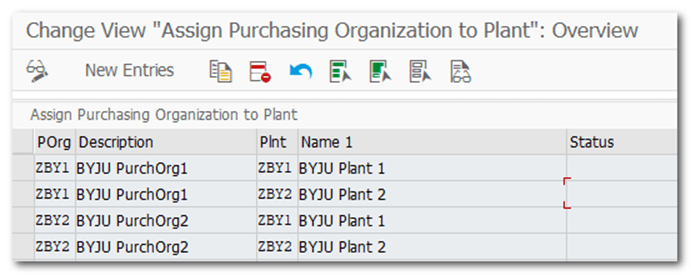

| Step 7 | Assign purchasing organization to plant |

| IMG | Enterprise Structure- Assignment- Materials Management- Assign purchasing organization to plant |

| Step 8 | Maintain Field Selection for Data Screens |

| IMG | Logistics – General- Material Master- Field Selection- Maintain Field Selection for Data Screens |

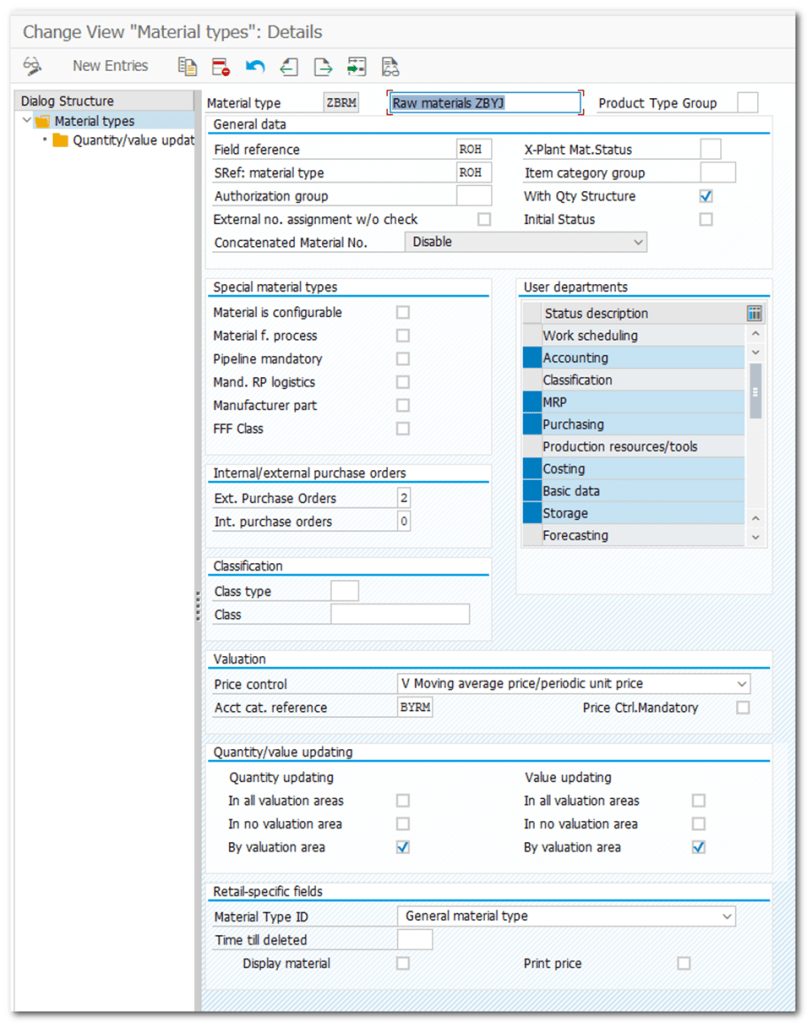

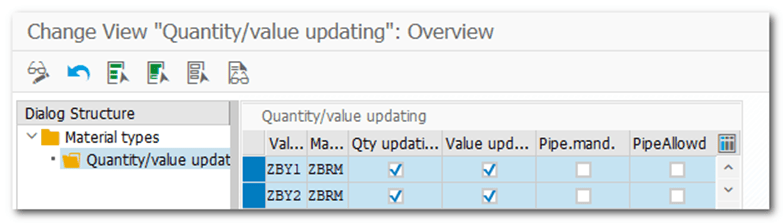

| Step 9 | Define Attributes of Material Types ZAPRM ZAPFG |

| IMG | Logistics – General- Material Master- Basic Settings- Material Types- Define Attributes of Material Types |

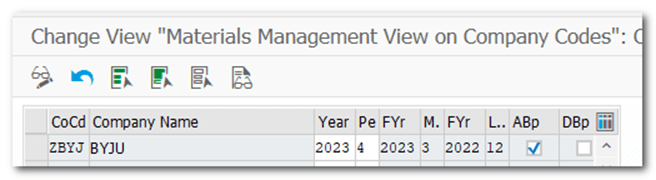

| Step 10 | Maintain Company Codes for Materials Management |

| IMG TCODE | Logistics – General- Material Master- Basic Settings- Maintain Company Codes for Materials Management OMSY |

| MMRV MMPV : Used for subsequent opening/closing of posting periods. |

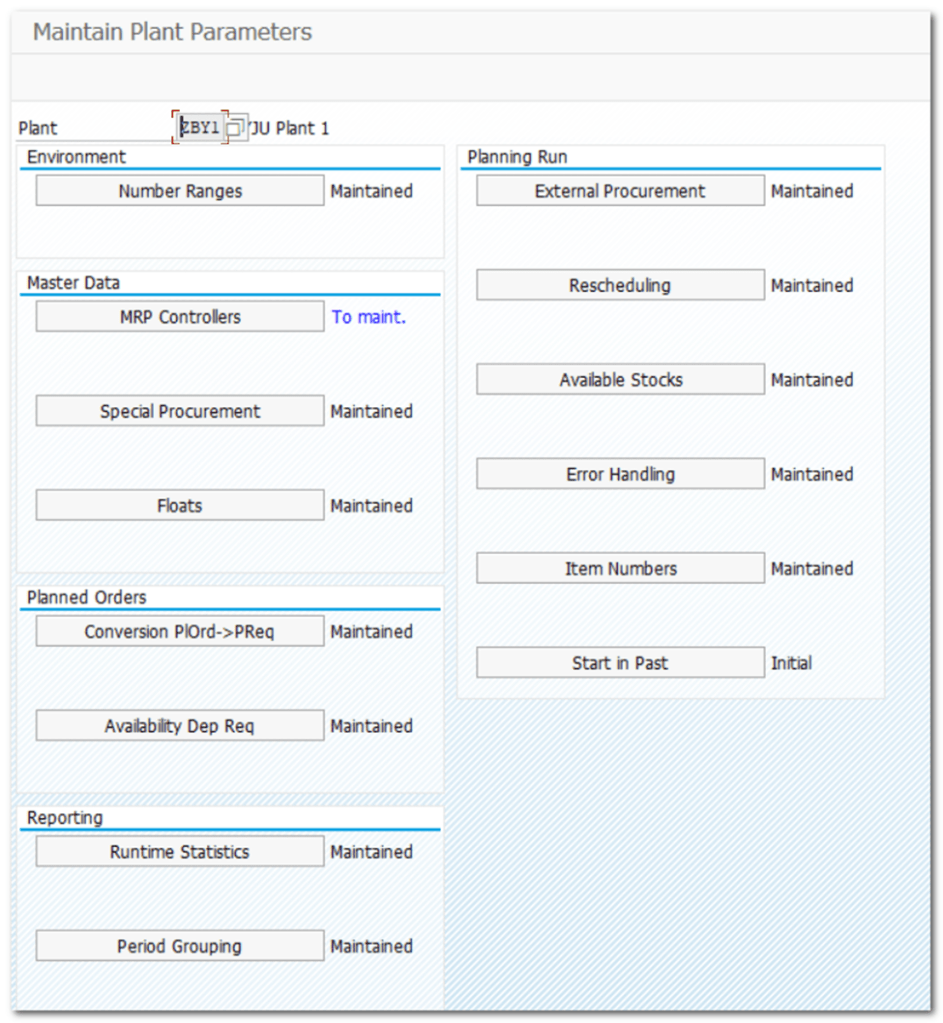

| Step 11 | Define Plant Parameters for MRP |

| IMG TCODE | Materials Management-Consumption-Based Planning-Plant Parameters-Carry Out Overall Maintenance of Plant Parameters OMI8 |

| Step 12 | Define Tax codes for incoming Invoices |

| IMG TCODE | Materials Management- Logistics Invoice Verification- Incoming Invoice- Maintain Default Values for Tax Codes |

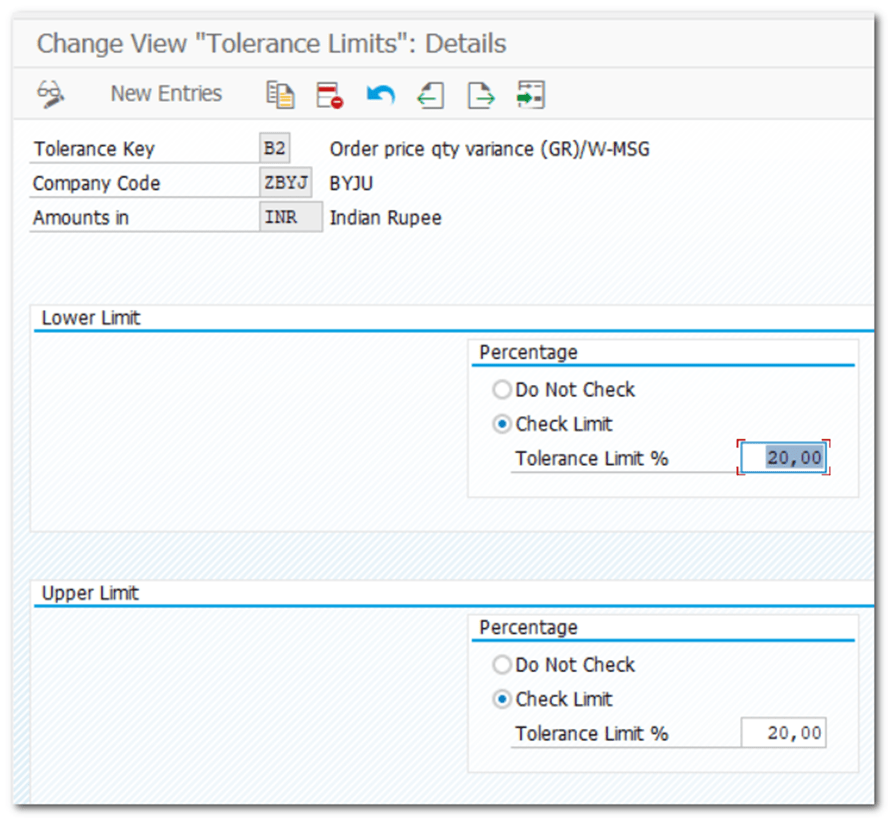

| Step 13 | Define Tolerance Limits for Goods Receipts |

| IMG TCODE | Materials Management- Inventory Management and Physical Inventory- Goods Receipt- Set Tolerance Limits |

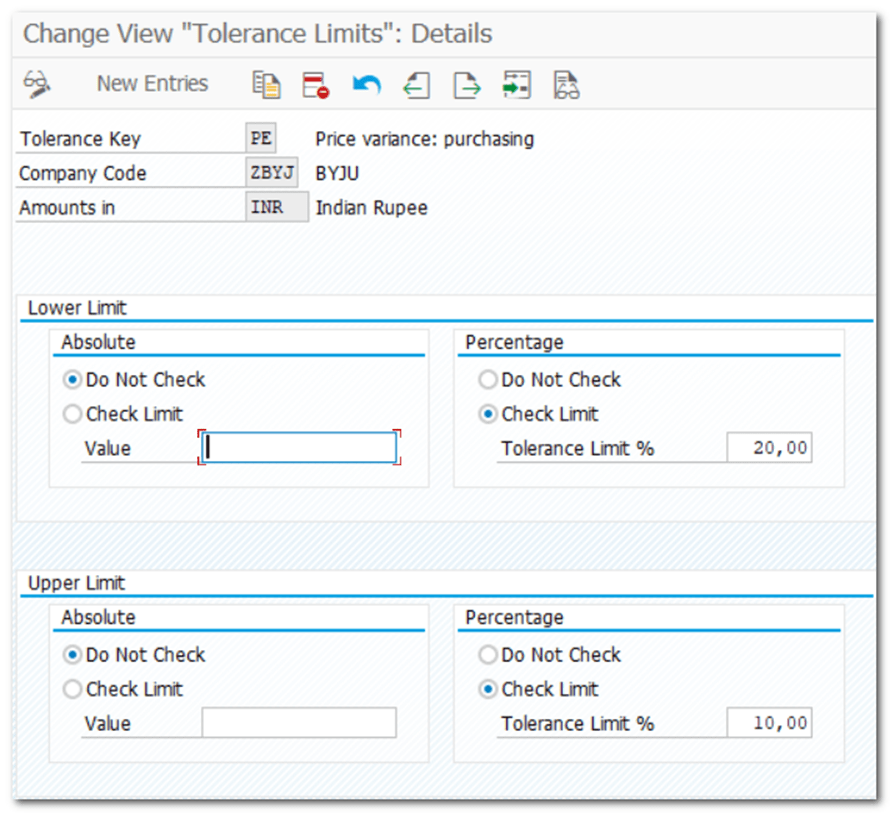

| Step 14 | Define Tolerance Limits for Price Variance |

| IMG TCODE | Materials Management- Purchasing- Purchase Order- Set Tolerance Limits for Price Variance |

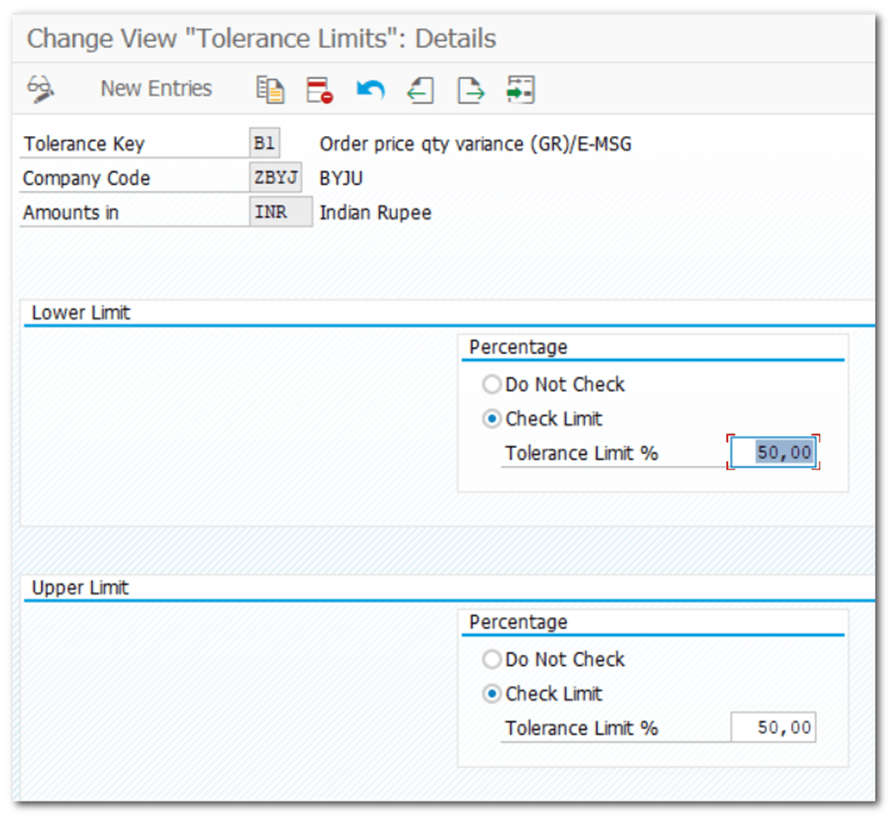

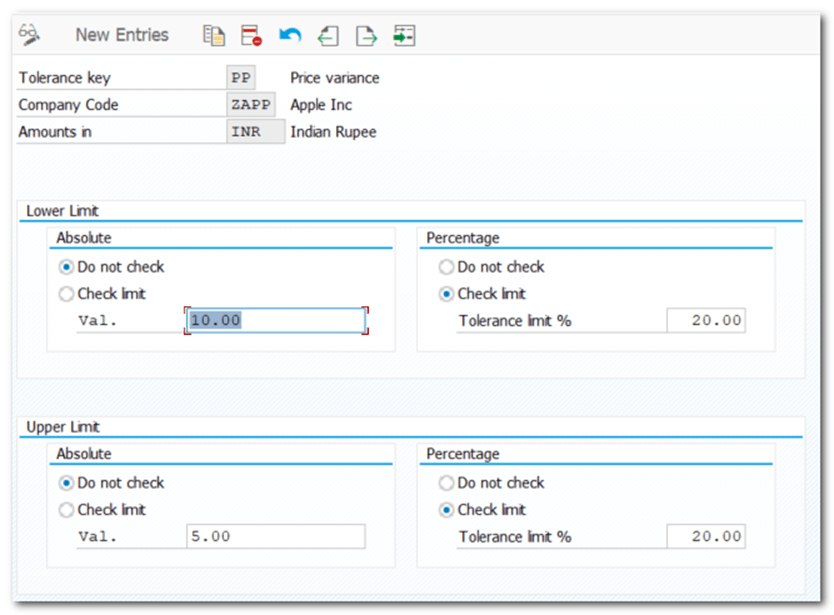

| Step 15 | Define Tolerance Limits while processing Invoice |

| IMG TCODE | Materials Management- Logistics Invoice Verification- Invoice Block- Set Tolerance Limits OMR6 |

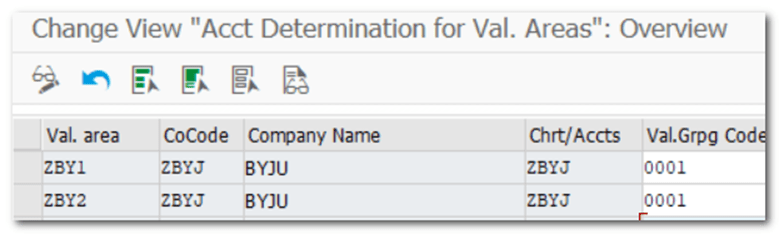

| Step 16 | Define Valuation Control |

| IMG TCODE | Materials Management- Valuation and Account Assignment- Account Determination- Account Determination Without Wizard- Group Together Valuation Areas |

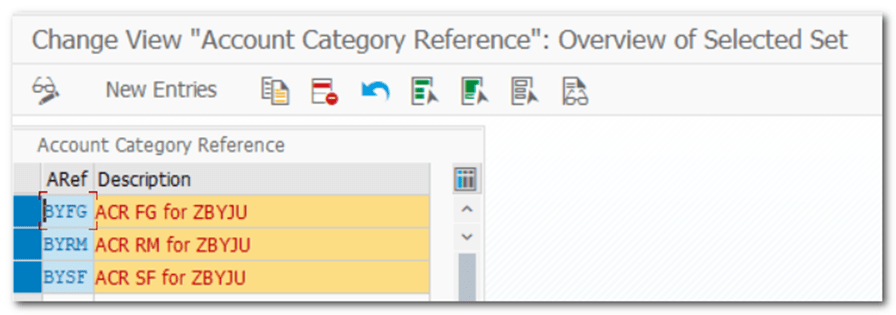

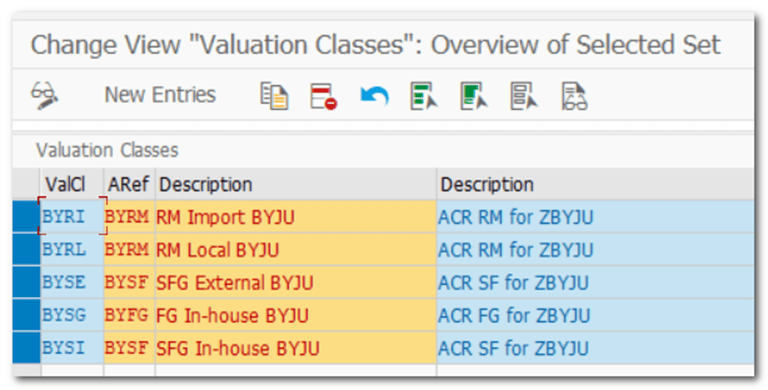

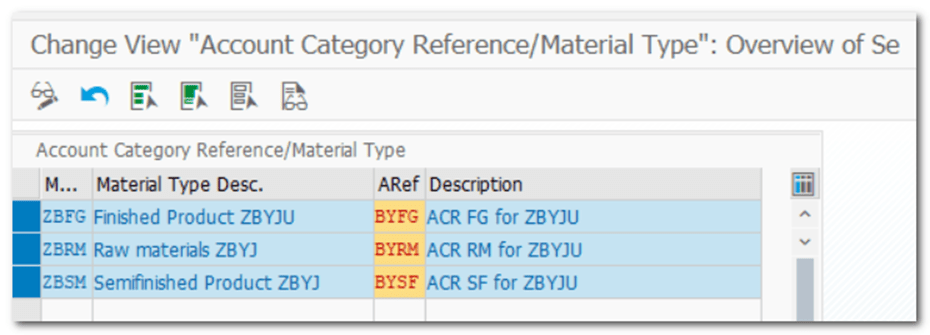

| Step 17 | Define Valuation Classes |

| IMG TCODE (OMSK) | Materials Management- Valuation and Account Assignment- Account Determination- Account Determination Without Wizard- Define Valuation Classes Account Category Reference Valuation Class Material Type/Account Category REference |

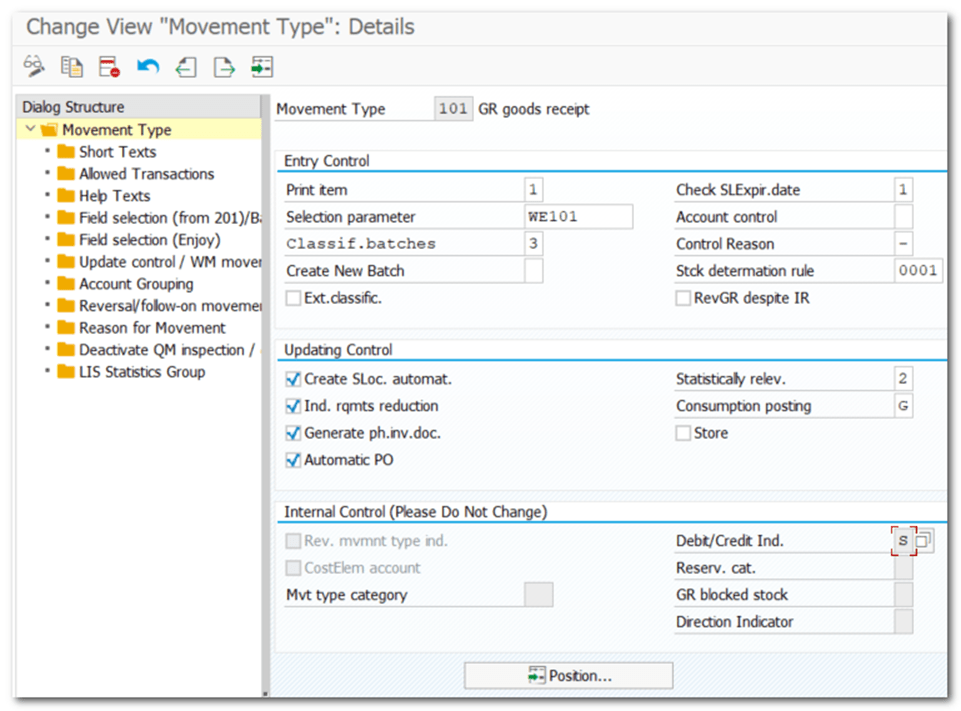

| Step 18 | Movement Types |

| IMG | Materials Management- Inventory Management and Physical Inventory- Copy, Change Movement Types |

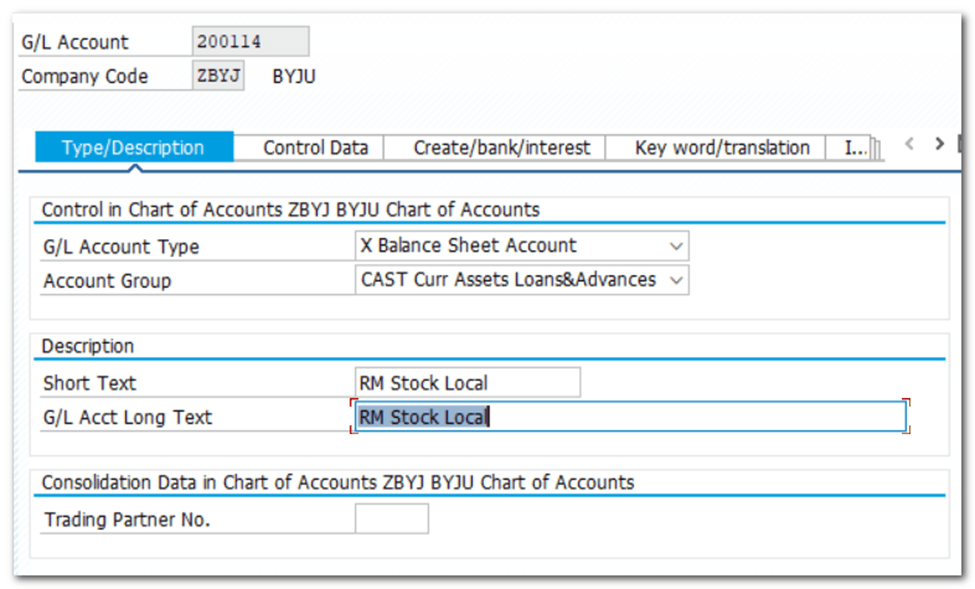

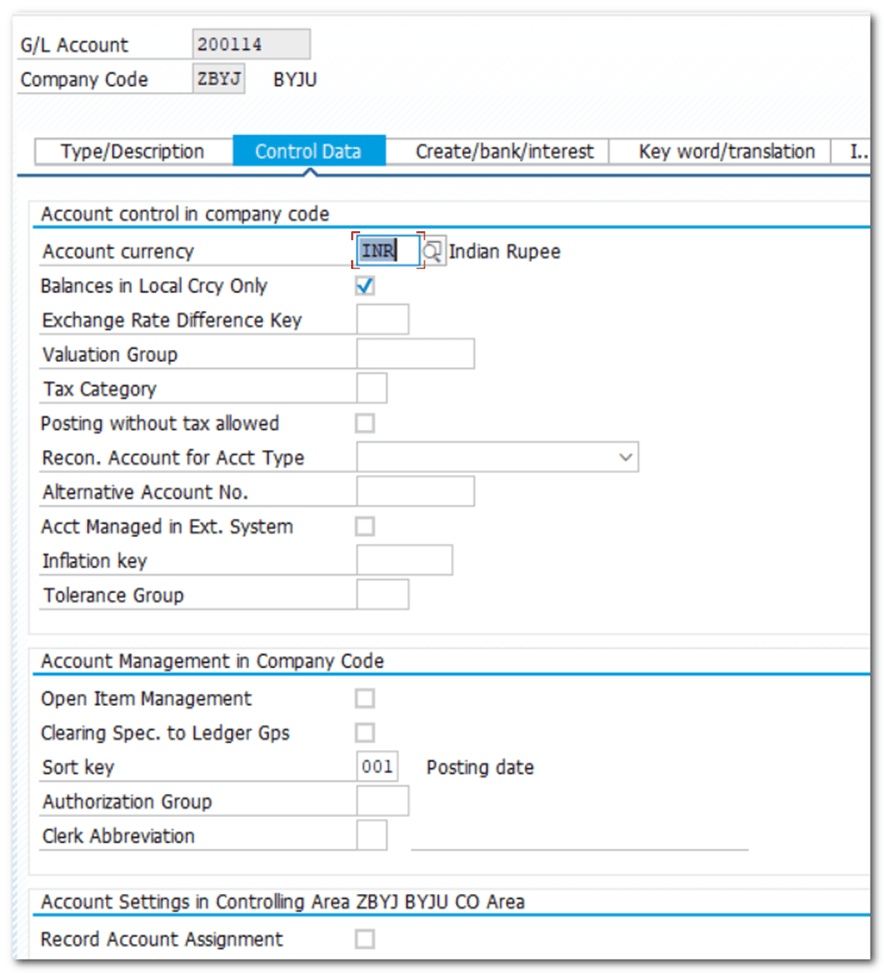

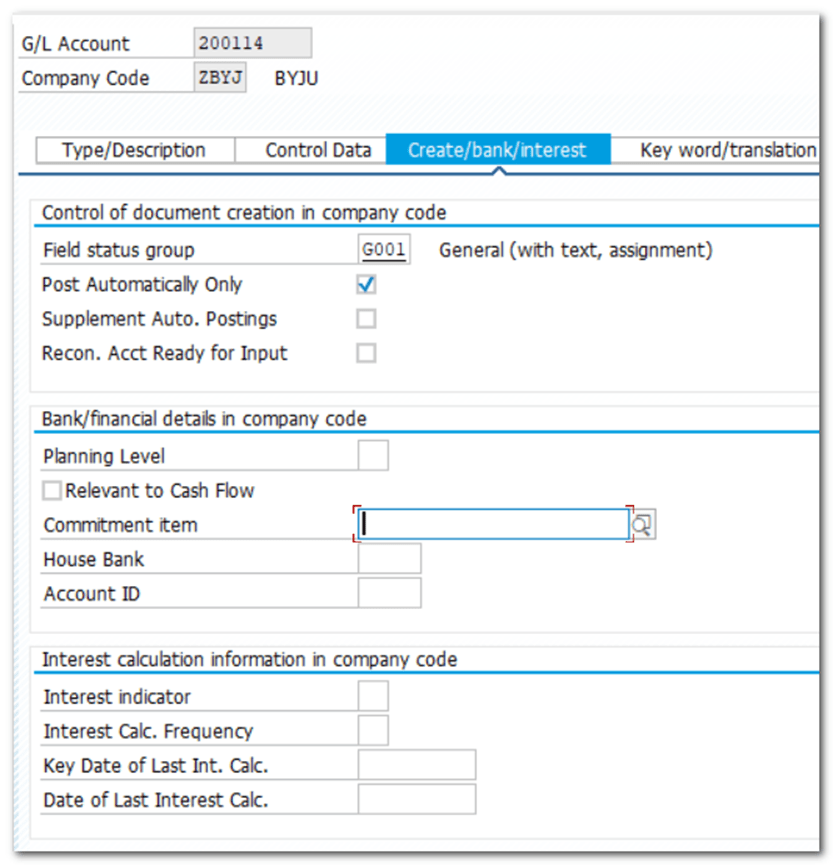

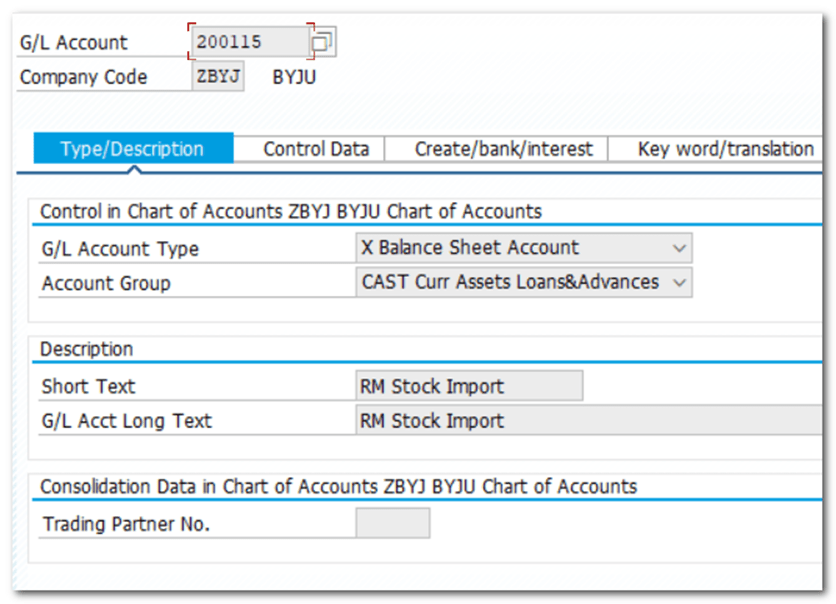

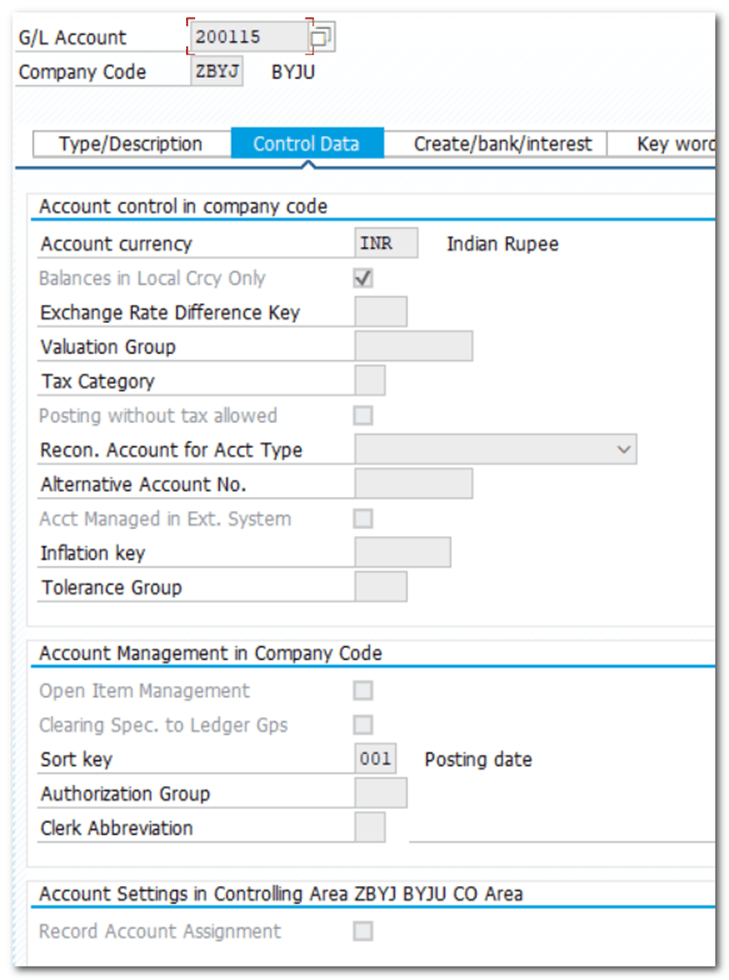

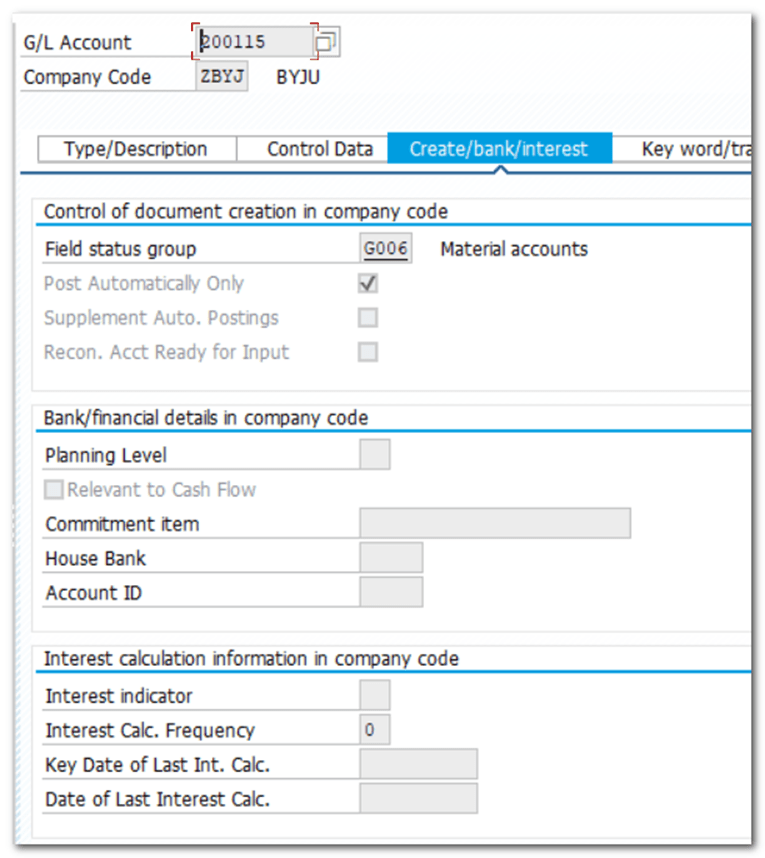

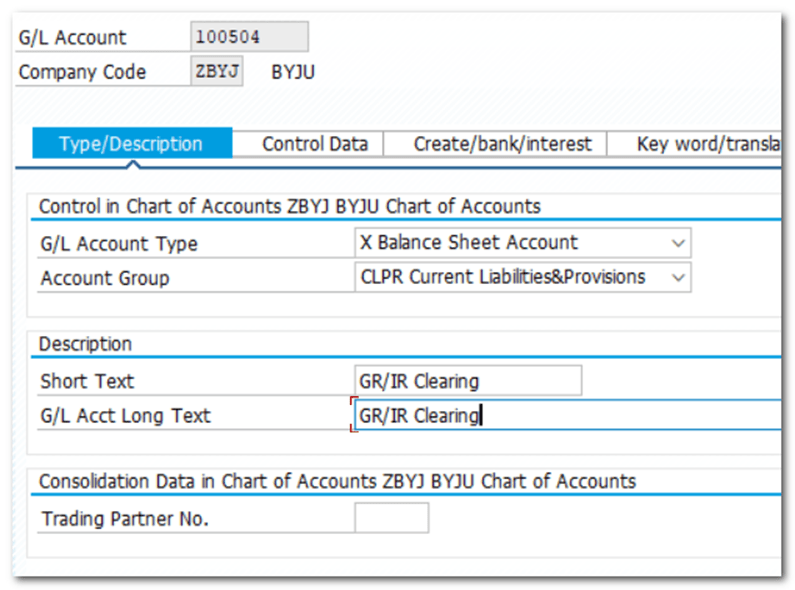

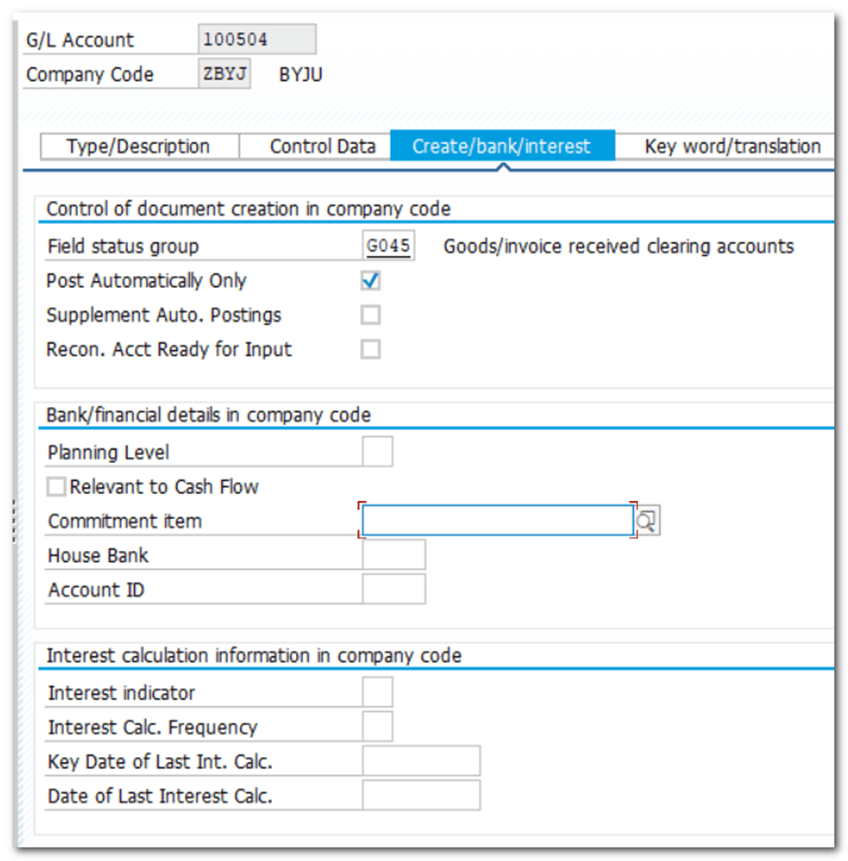

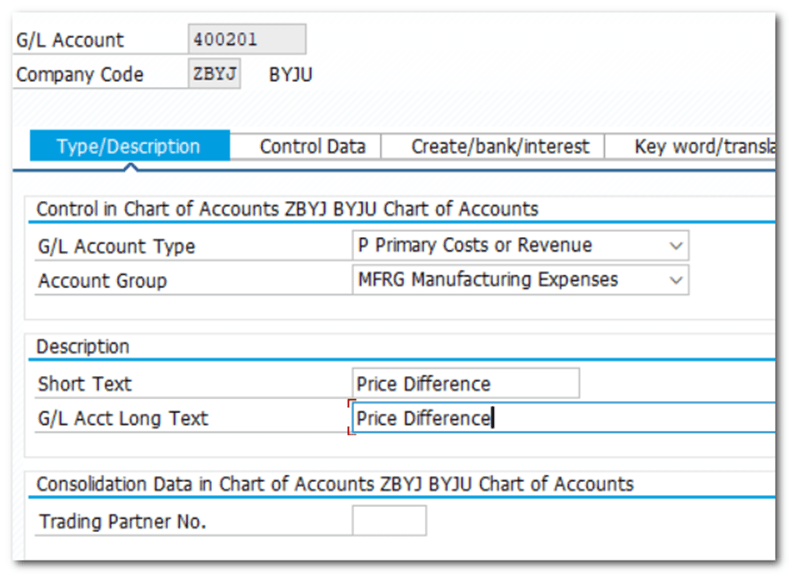

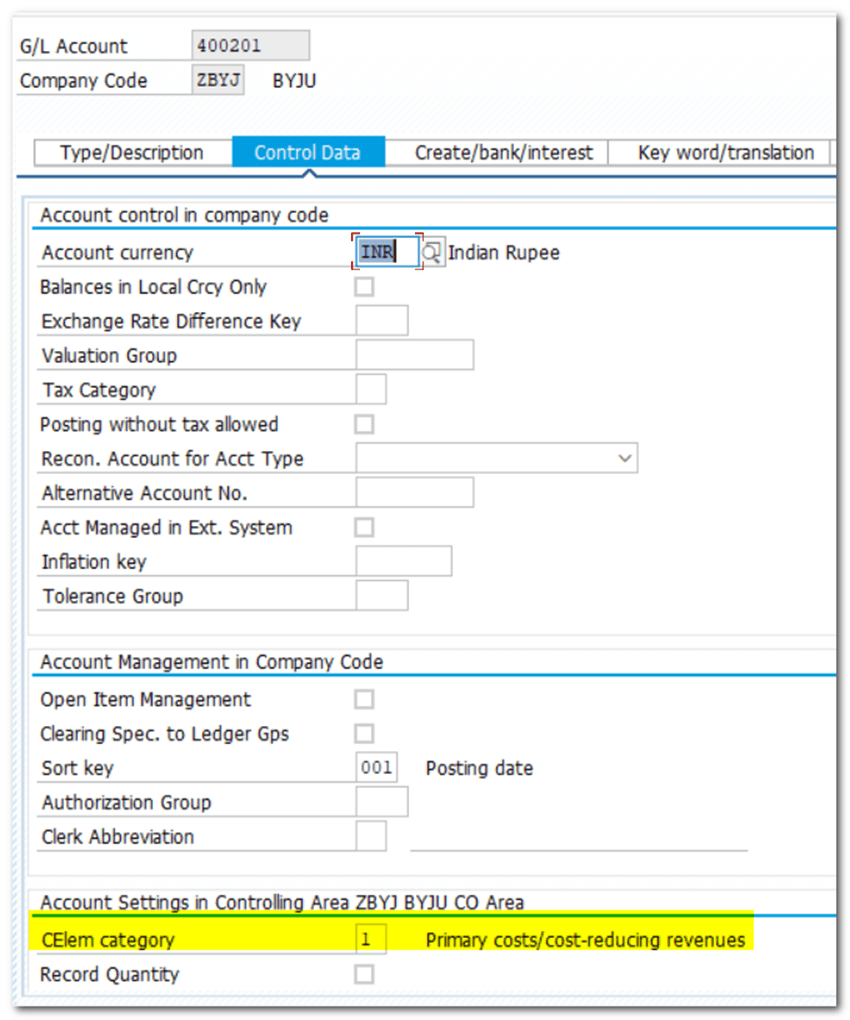

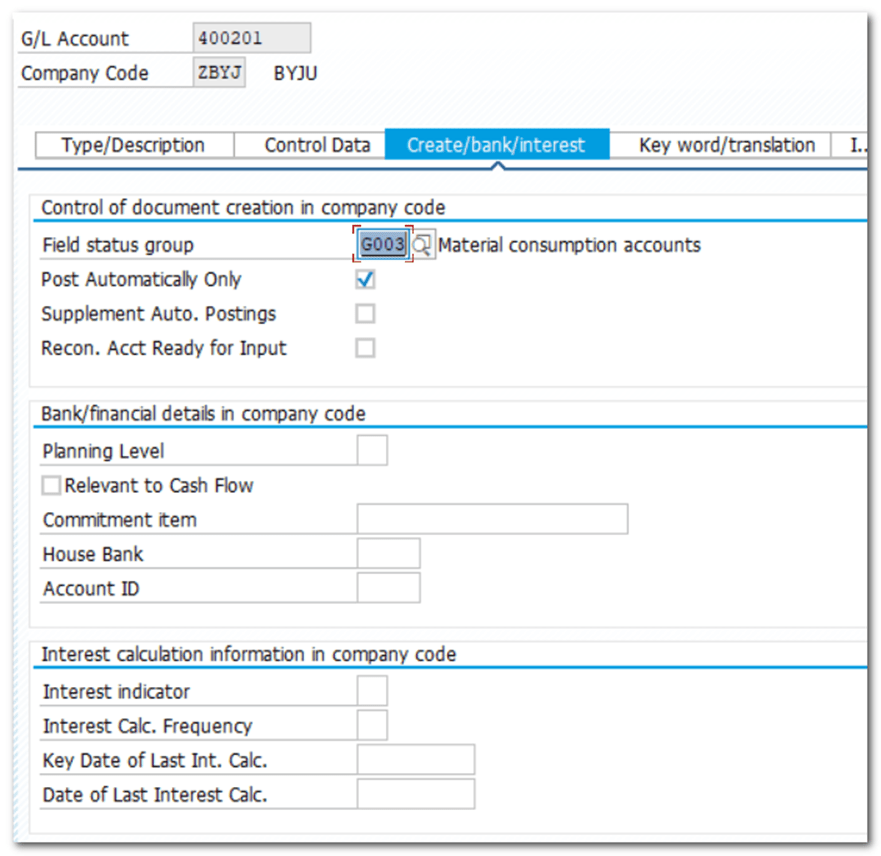

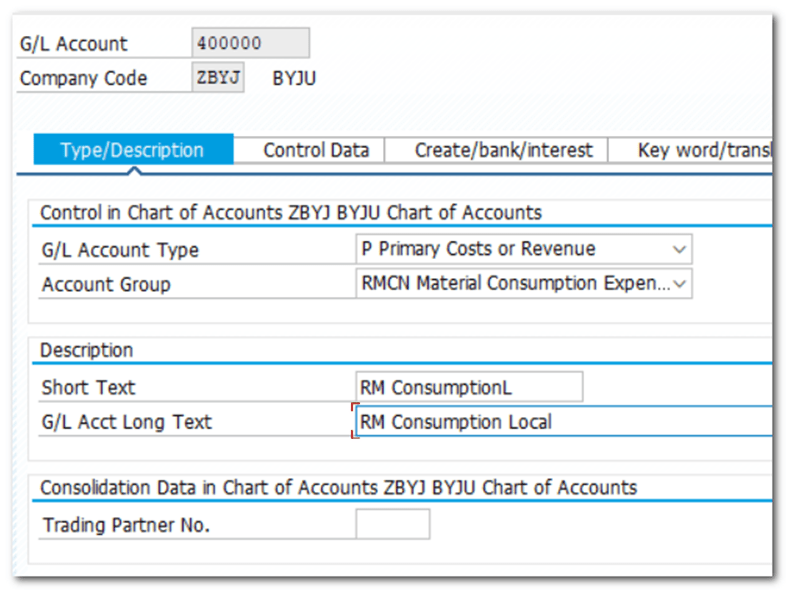

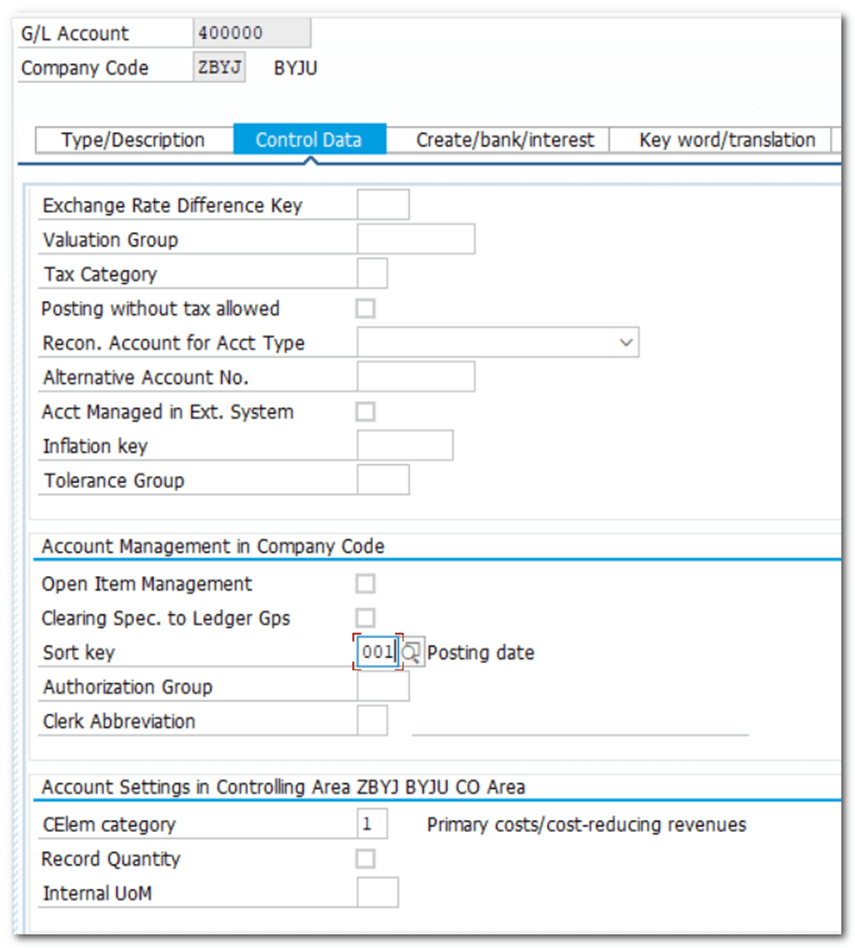

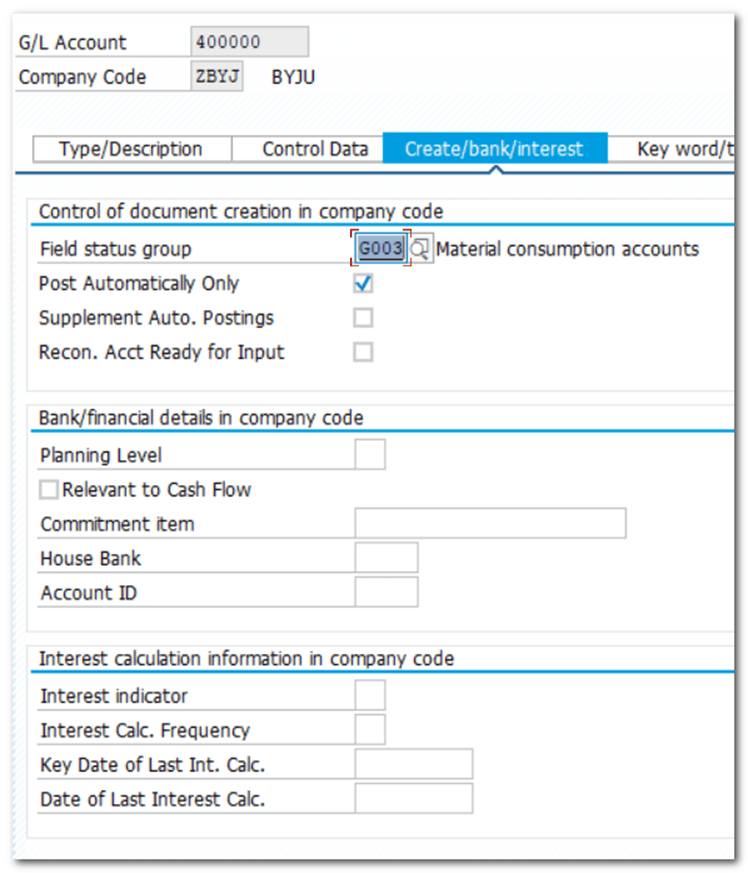

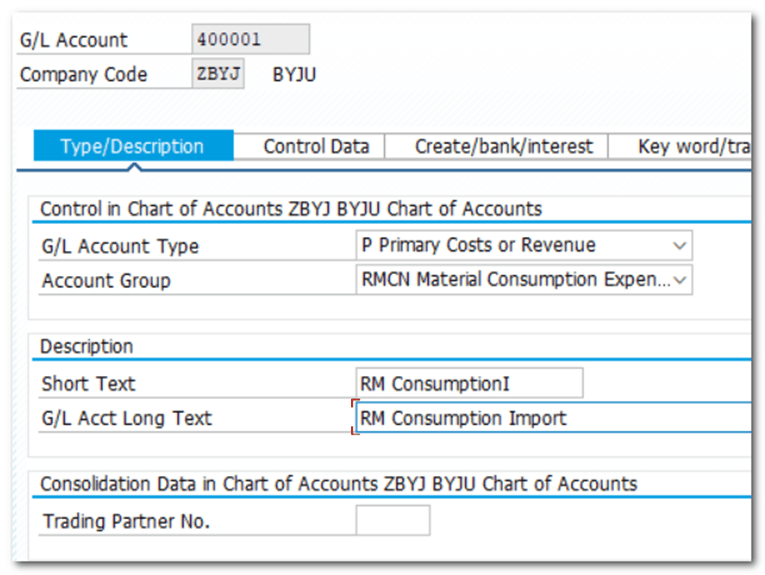

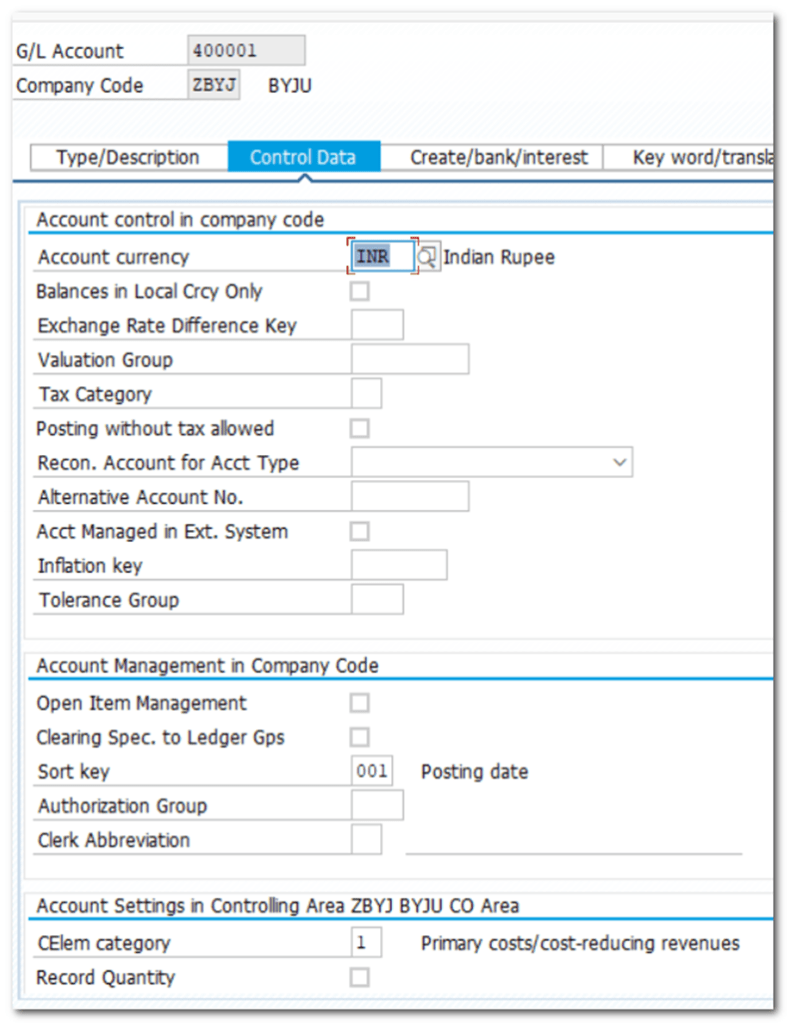

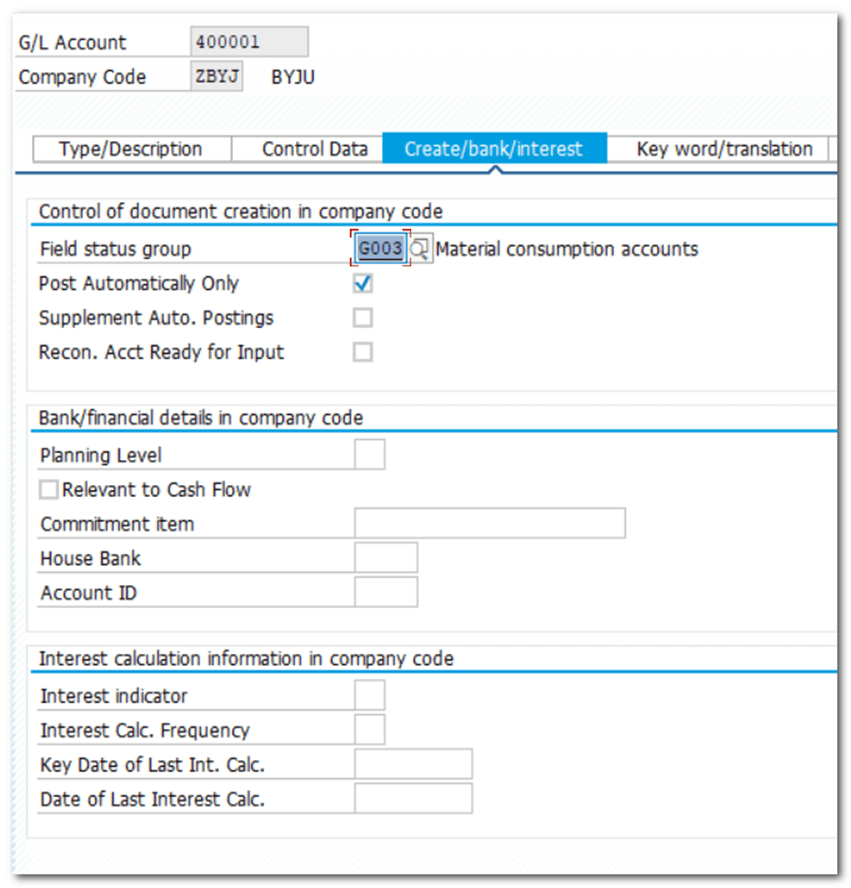

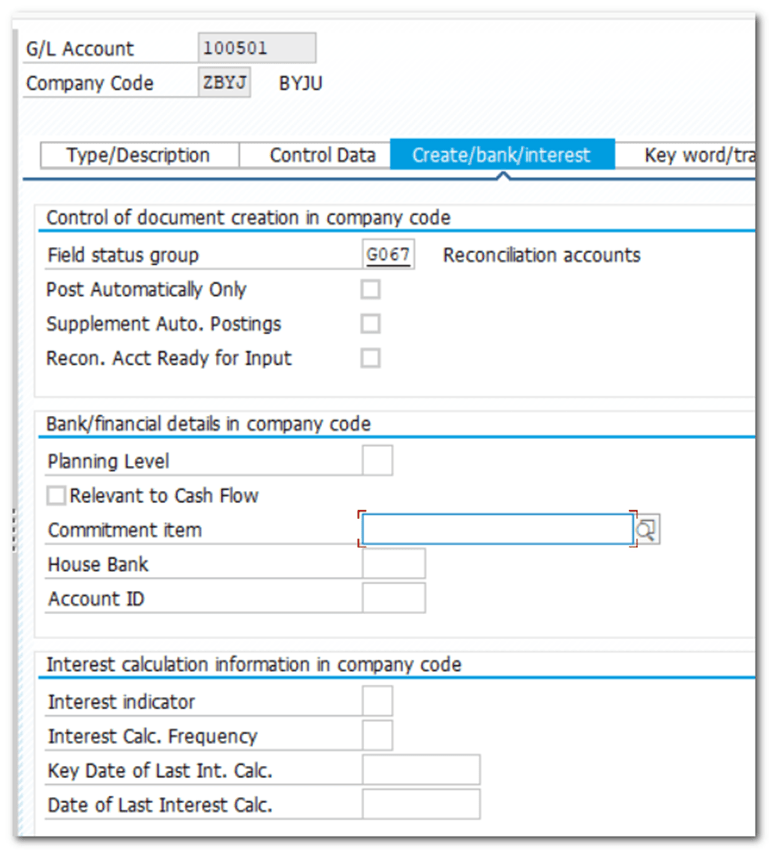

| Step 19 | Create GL |

| TCODE | FS00 |

| 200114 RM Stock Local 200115 RM Stock Import 100504 GR/IR Clearing 400201 Price Difference 400000 RM Consumption Local 400001 RM Consumption Import |

Raw Material Stock Import

GR/IR Clearing A/C

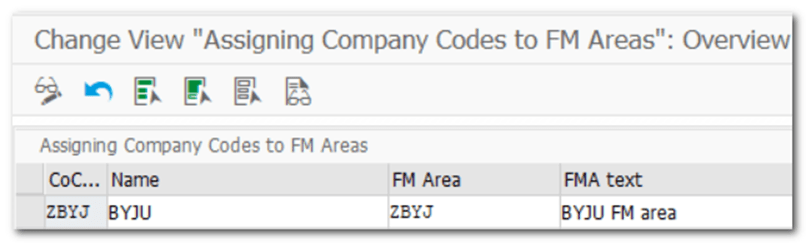

| Step 20 | Assign company code to financial management area |

| IMG | Enterprise Structure-Assignment-Financial Accounting-Assign company code to financial management area |

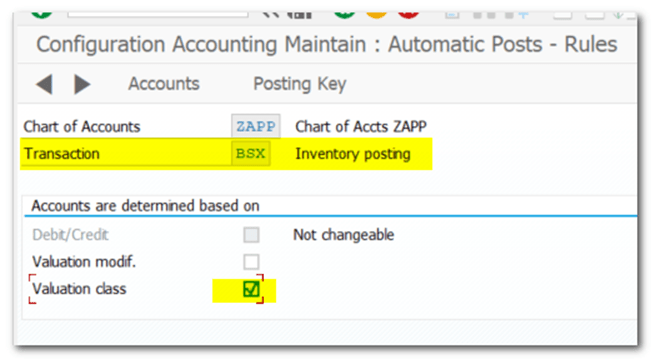

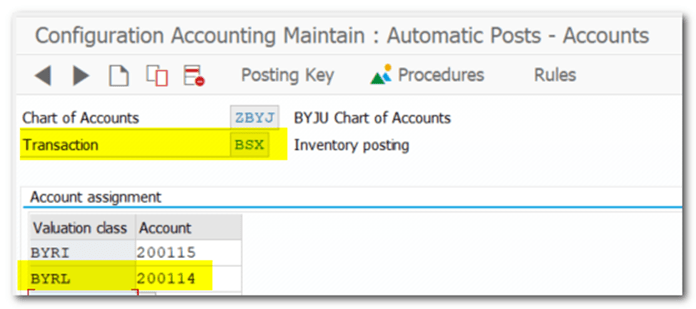

| Step 21 | Assignment of Accounts for Automatic Posting BSX |

| TCODE 200114 RM Stock Local 200115 RM Stock Import | Materials Management- Valuation and Account Assignment- Account Determination- Account Determination Without Wizard- Configure Automatic Postings OBYC |

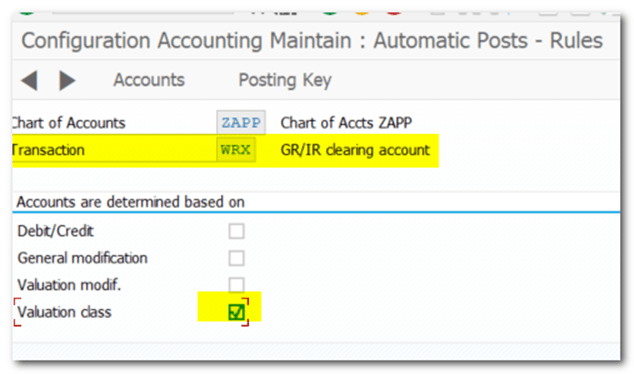

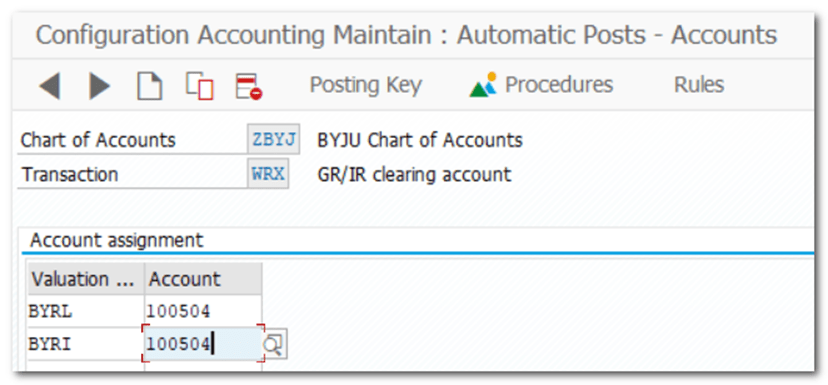

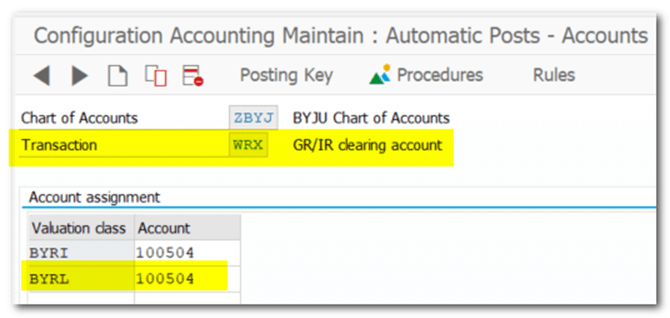

| Step 22 | Assignment of Accounts for Automatic Posting WRX |

| TCODE 100504 GR/IR Clearing | Materials Management- Valuation and Account Assignment- Account Determination- Account Determination Without Wizard- Configure Automatic Postings OBYC |

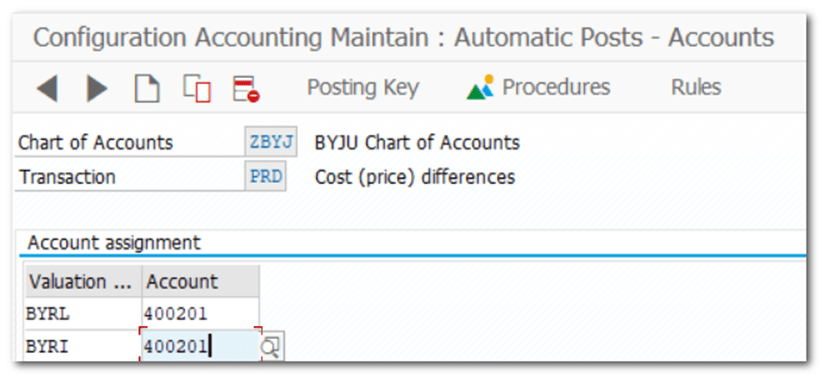

| Step 23 | Assignment of Accounts for Automatic Posting PRD |

| TCODE 400201 Price Difference | Materials Management- Valuation and Account Assignment- Account Determination- Account Determination Without Wizard- Configure Automatic Postings OBYC |

| Step 24 | Assignment of Accounts for Automatic Posting GBB |

| TCODE | Materials Management- Valuation and Account Assignment- Account Determination- Account Determination Without Wizard- Configure Automatic Postings OBYC 400000 RM Consumption Local 400001 RM Consumption Import |

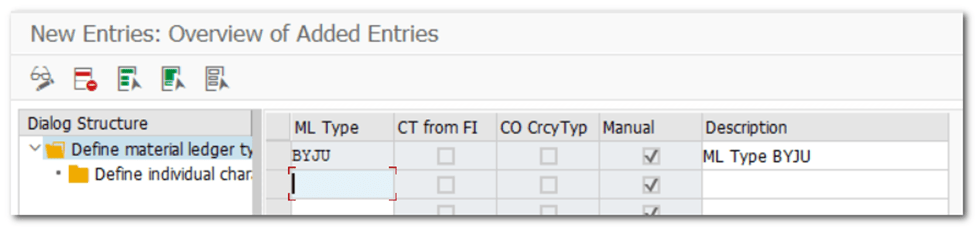

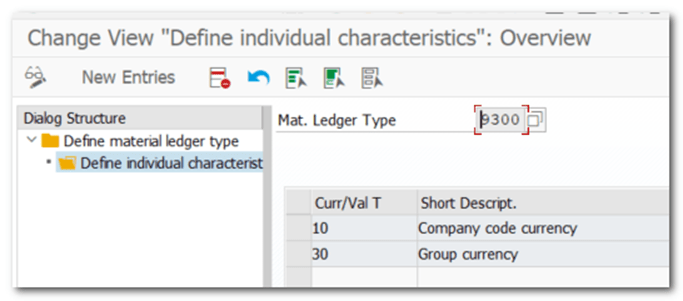

| Step 25 | To do MM Postings Material Ledger mandatory in S4 |

| TCODE | OMX2 |

| Step 26 | Assign ML to Valuation Area (Plant) |

| TCODE | OMX3 |

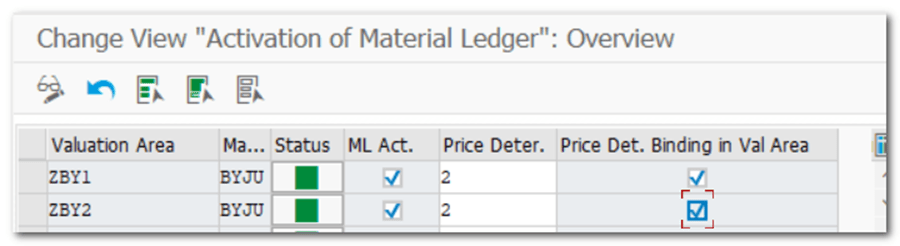

| Step 27 | Activation of Material Ledger |

| TCODE | OMX1 |

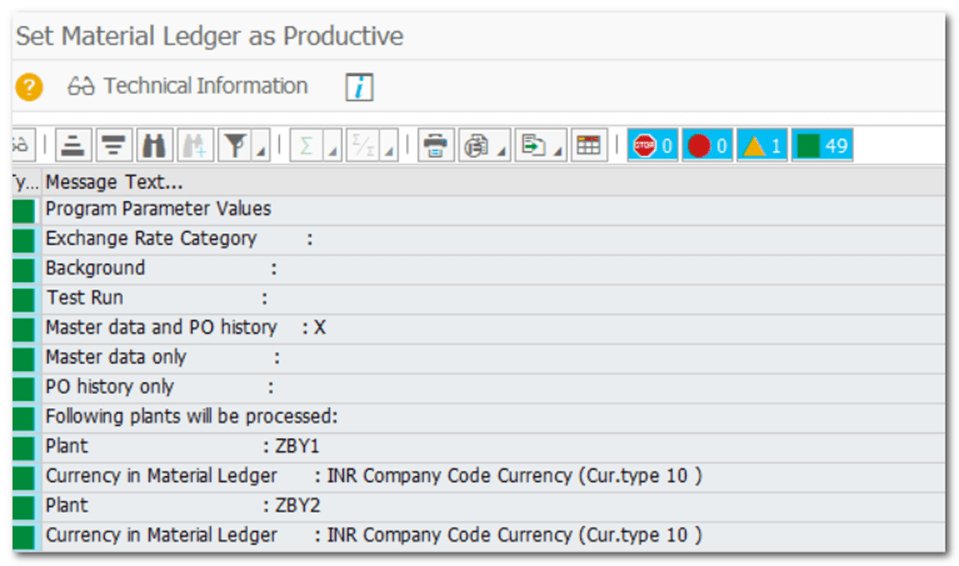

| Step 28 | Set Valuation Areas as Productive |

| TCODE | CKMSTART Material Master- Environment- Material Ledger- Environment- Production Startup- CKMSTART – Set Valuation Areas as Productive |

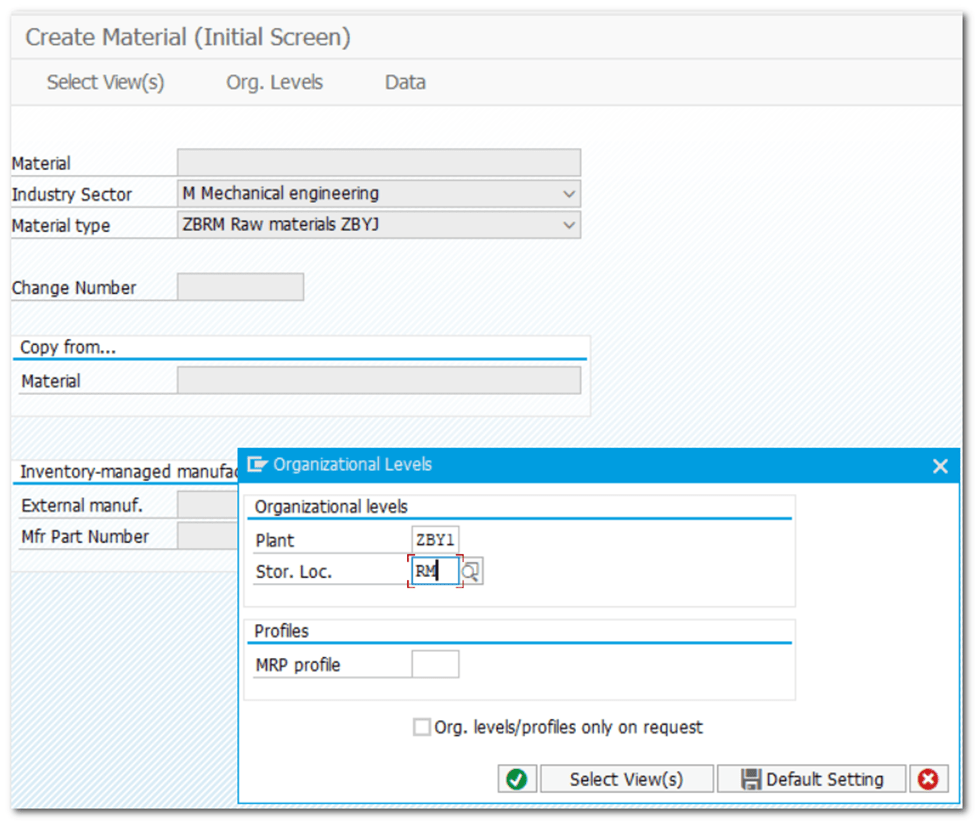

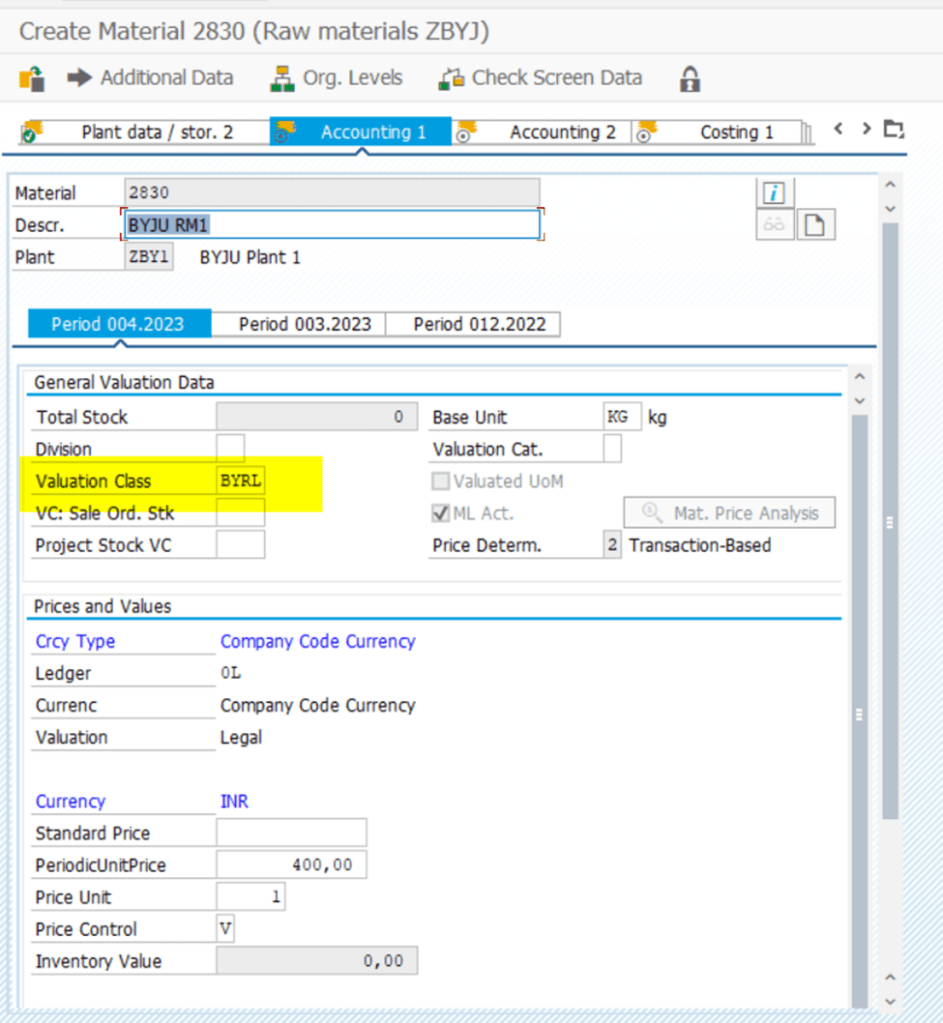

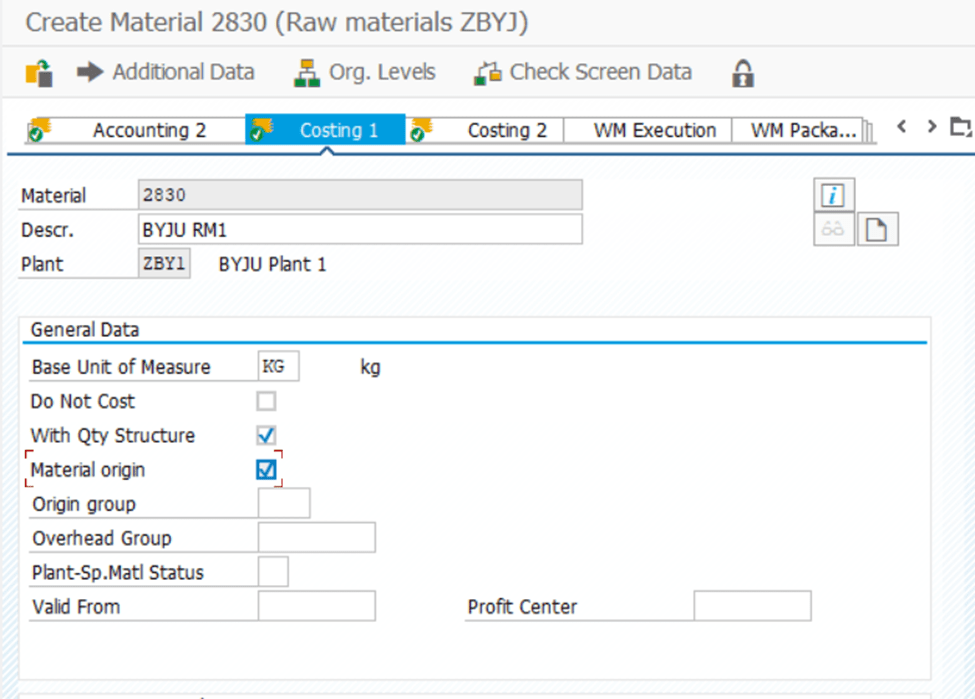

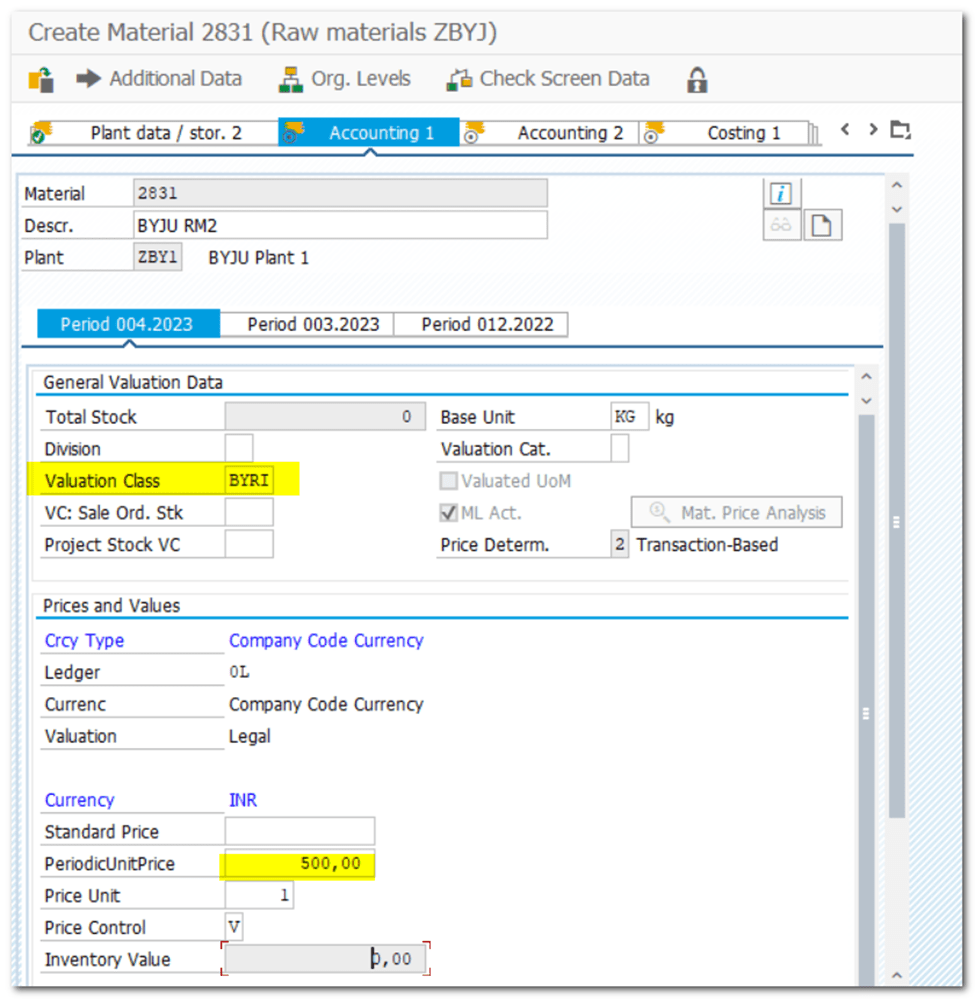

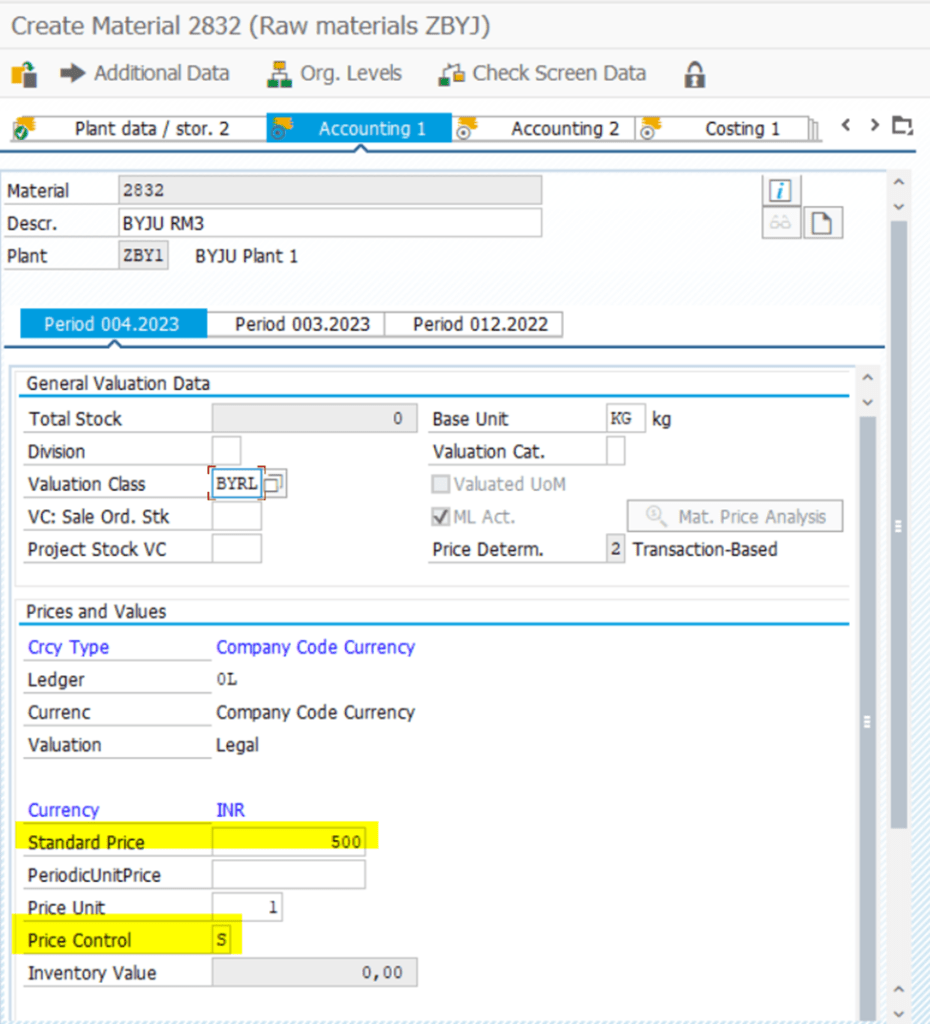

| Step 29 | Create Material Master |

| TCODE | MM01 |

Material 2830 created

Material 2831 created

Material 2832 created

| Step 30 | Create Vendor Master |

| TCODE | XK01/BP |

| PAT |

LFA1 – GENERAL DATA

LFB1 – COMPANY CODE

LFM1- PURCHASING DATA

LFC1 – TRANSACTIONAL DATA

ACDOCA/MATTDOC – S4 TRANSACTONAL DATA

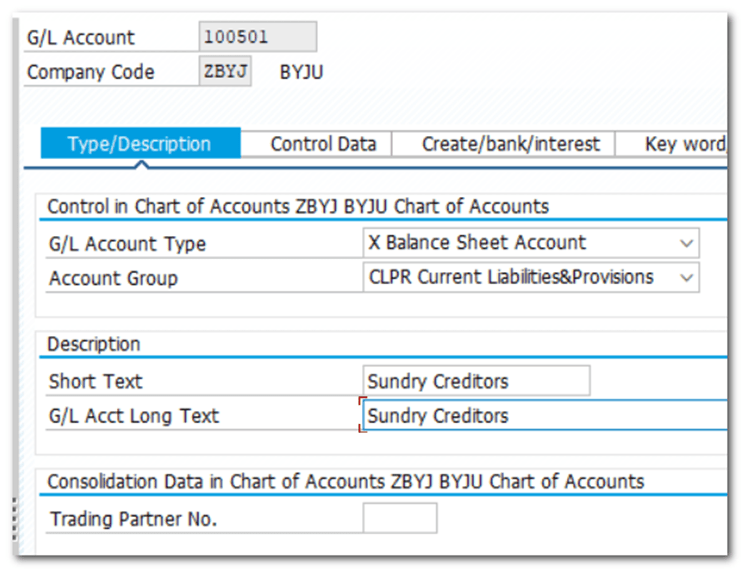

| Step 31 | Sundry Creditors |

| TCODE | FS00 |

| Step 32 | Create PO |

| TCODE | ME21N |

| Vendor | PAT |

Standard PO created under the number 4500004775

| Step 33 | Maintain Number Range |

| IMG SNRO OBA7 | MM- Inventory Management and Physical Inventory- Define Number Assignment for Accounting Documents |

| WA – Goods Issue WE – Goods Receipt RE – Invoice Receipt |

Interval 50 does not exist for object RF_BELEG ZAPP FBN1

Maintained Number Range in SNRO

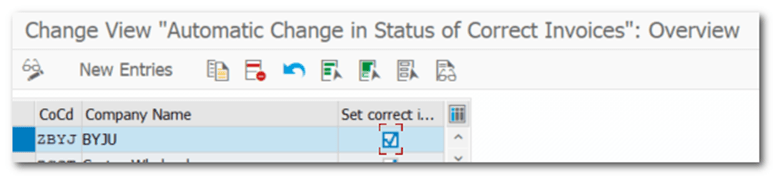

| Step 34 | Define Automatic Status Change |

| IMG SNRO | MM- Logistics Invoice Verification- Invoice Verification in Background- Define Automatic Status Change |

Table T169P: entry ZBYJ does not exist

Message No. M8100

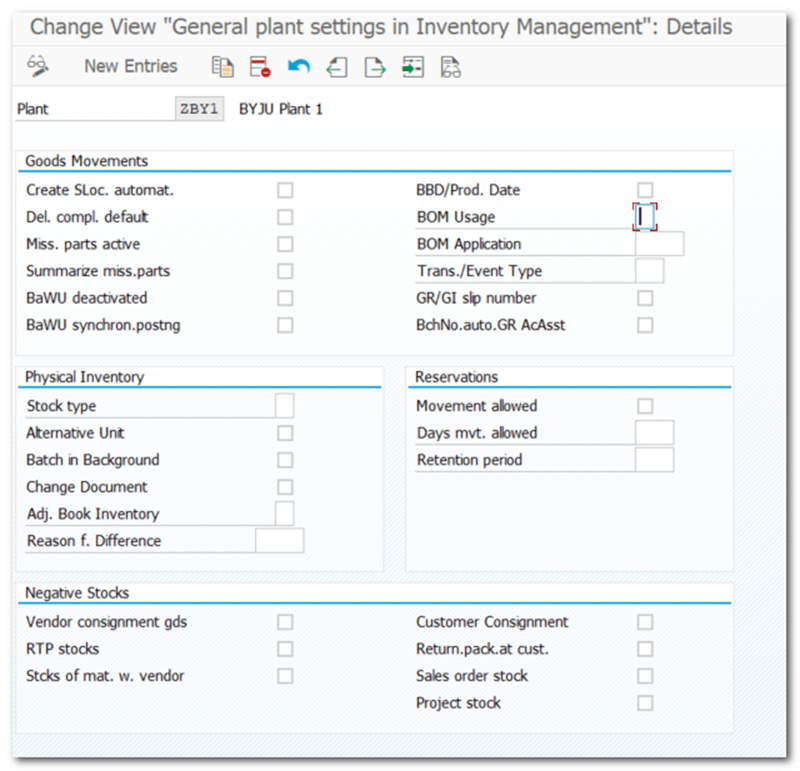

| Step 35 | Maintain Plant Parameters |

| IMG | MM- Inventory Management and Physical Inventory- Plant Parameters |

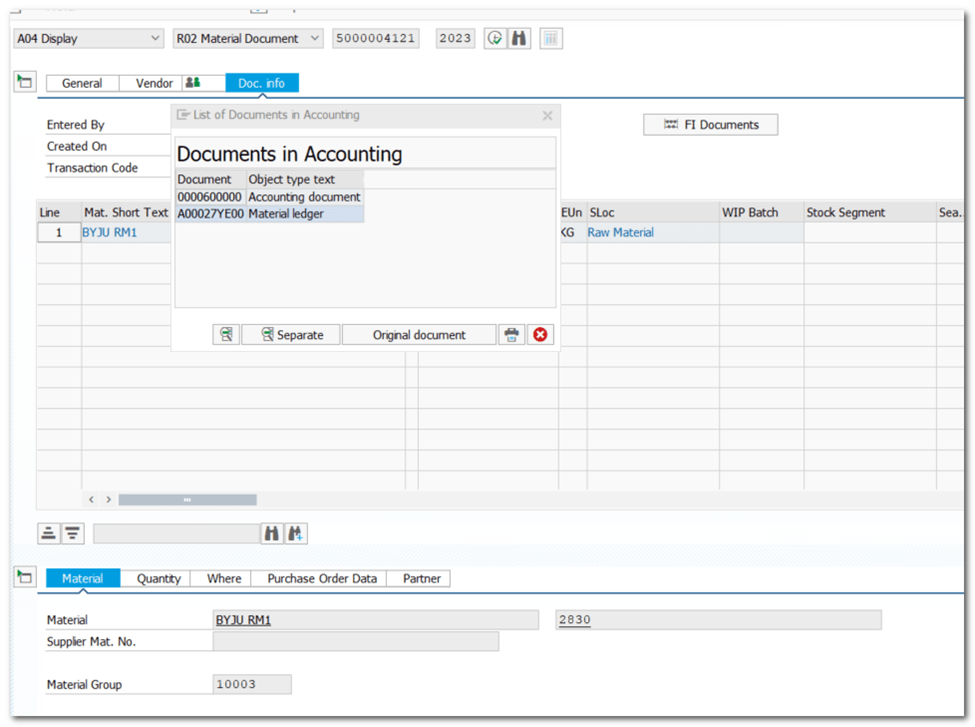

| Step 36 | Goods Receipt |

| TCODE | MIGO |

| w.r.f to PO doc | 4500004775 |

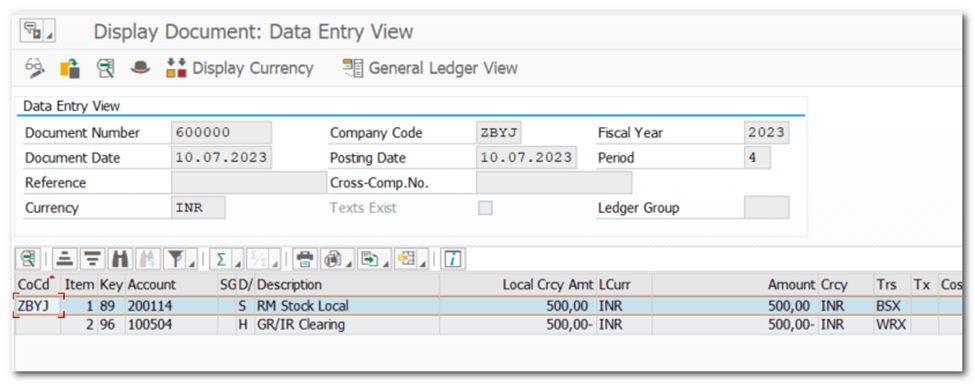

| RM Stock (Dr) GR/IR Clearing (Cr) | 100 (BSX) 100 (WRX) |

Material document 5000004121 posted

Message No. MIGO012

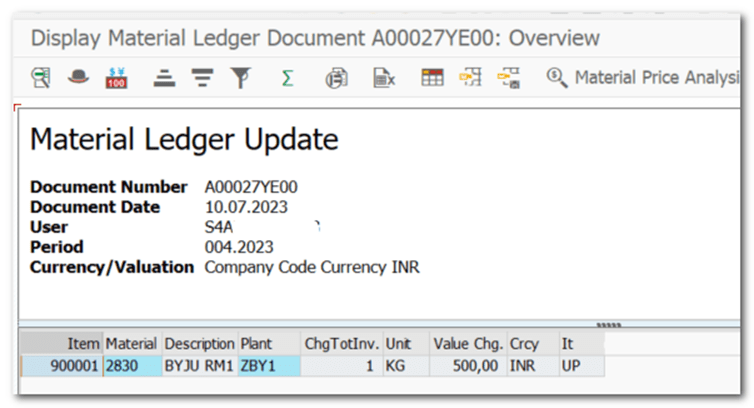

ML docs can be accessed from CKMS

OBYC

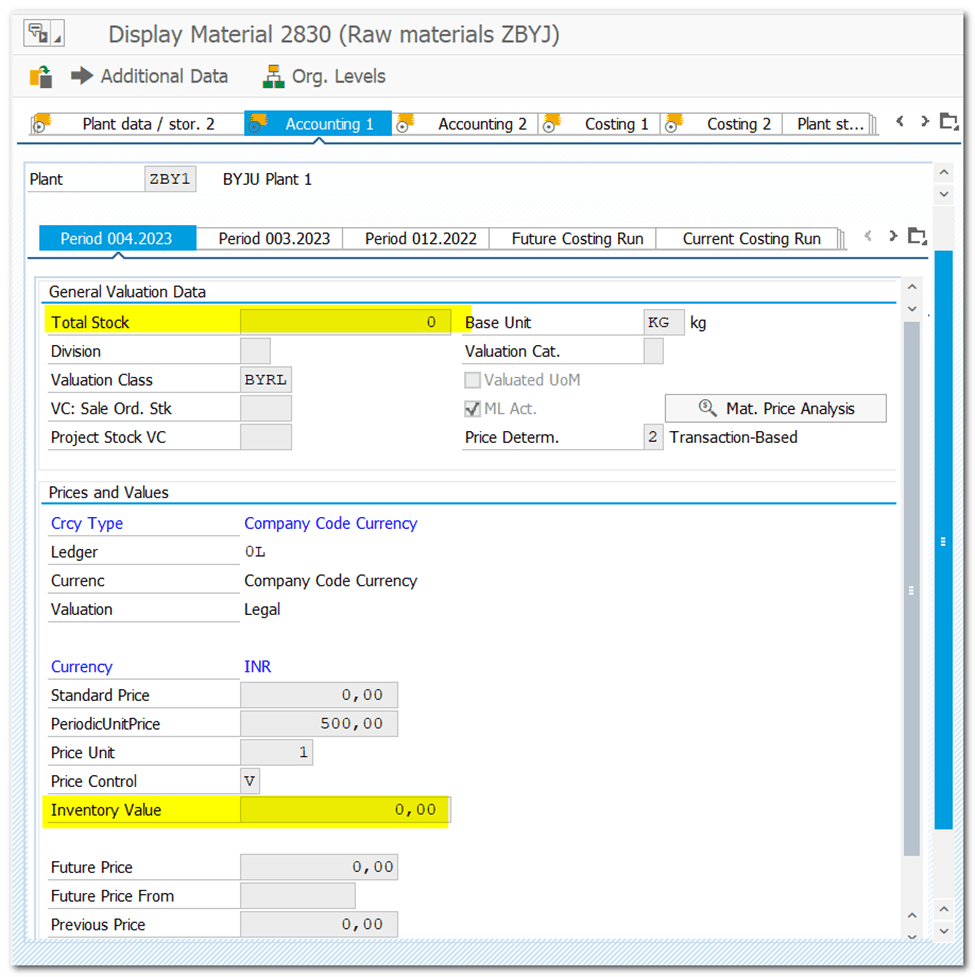

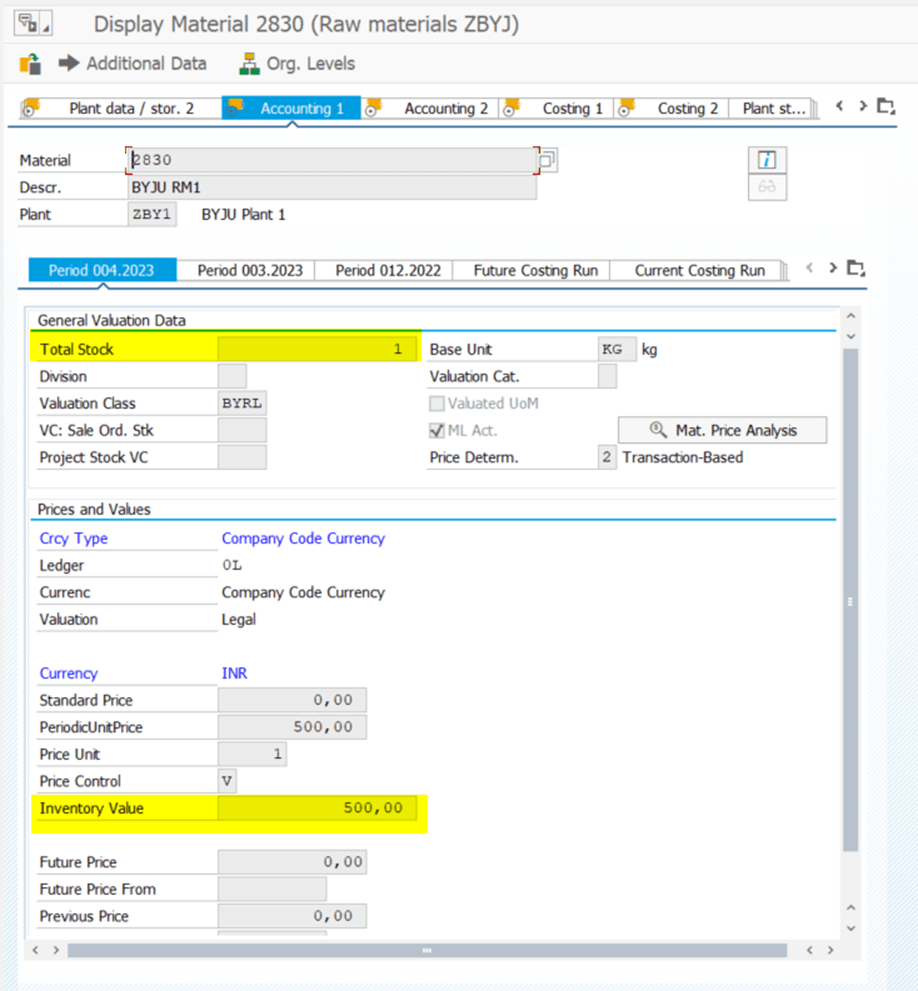

MM03: Check Valuation data (Total Stock, Inventory Value)

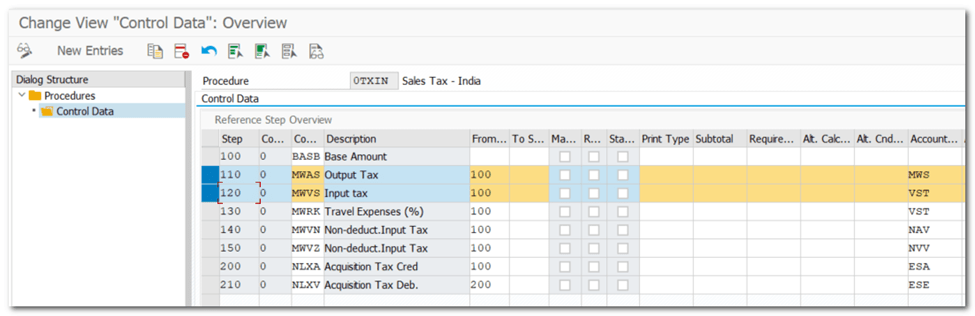

| Step 37 | Tax Procedure |

| IMG | Financial Accounting–Financial Accounting Global Settings-Tax on Sales/Purchases-Basic Settings- Check Calculation Procedure Assign Country to Calculation Procedure |

| Input Tax for Purchase Output Tax for Sales Account Key assigned to Condition Type Map G/L account for Account Key |

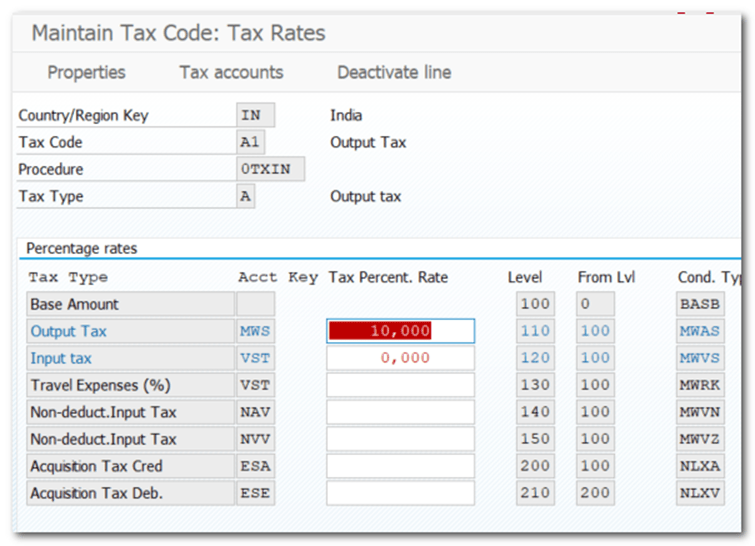

| Step 38 | Define Tax Codes for Sales and Purchases |

| TCODE | FTXP Financial Accounting–Financial Accounting Global Settings-Tax on Sales/Purchases- Calculation- Define Tax Codes for Sales and Purchases |

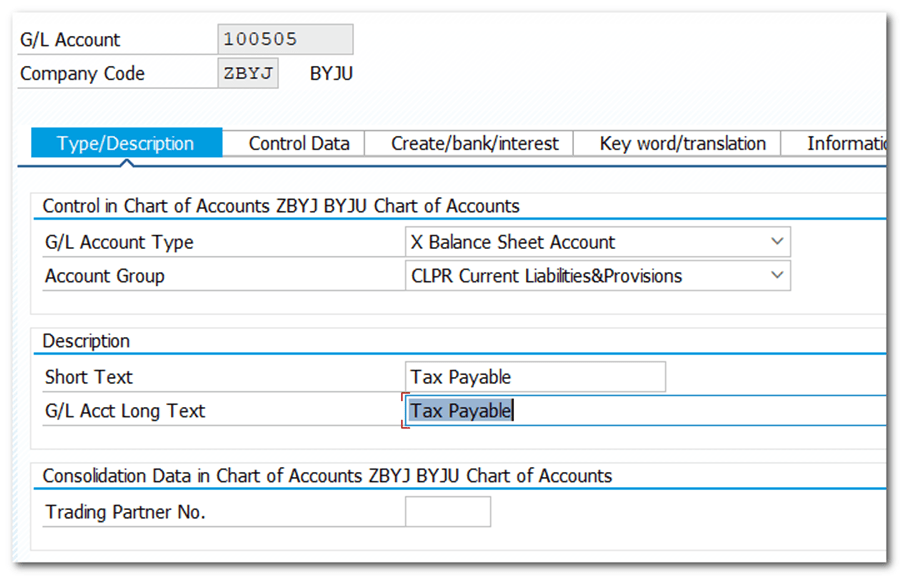

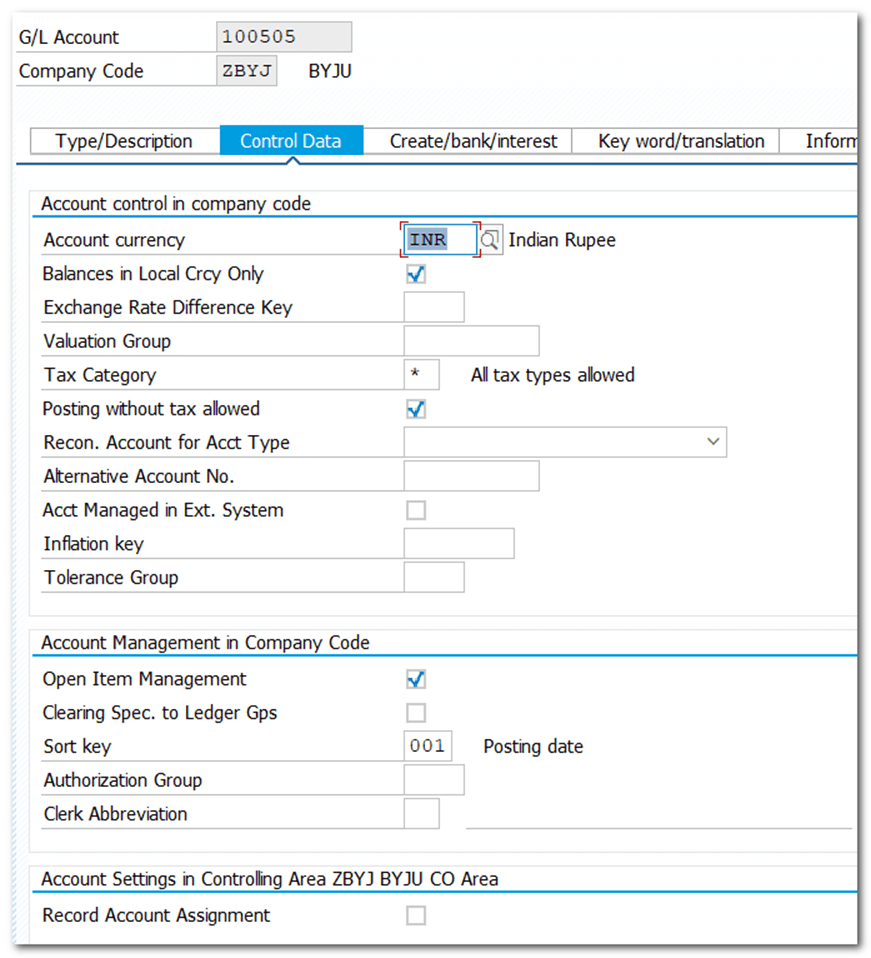

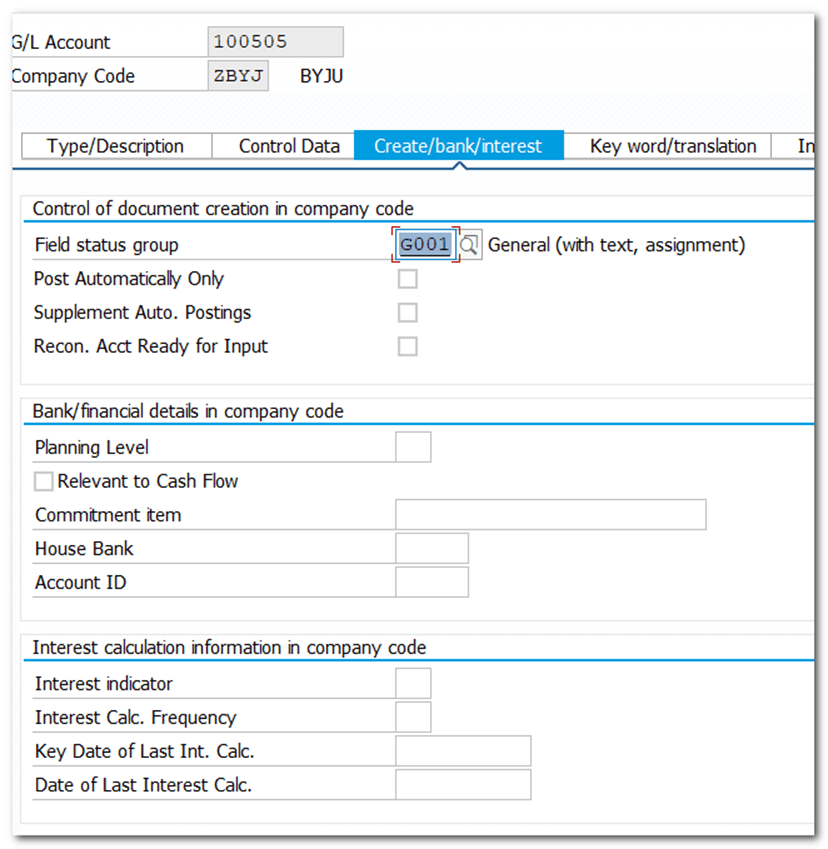

| Step 37 | Creation of Tax Payable Account |

| TCODE | FS00 |

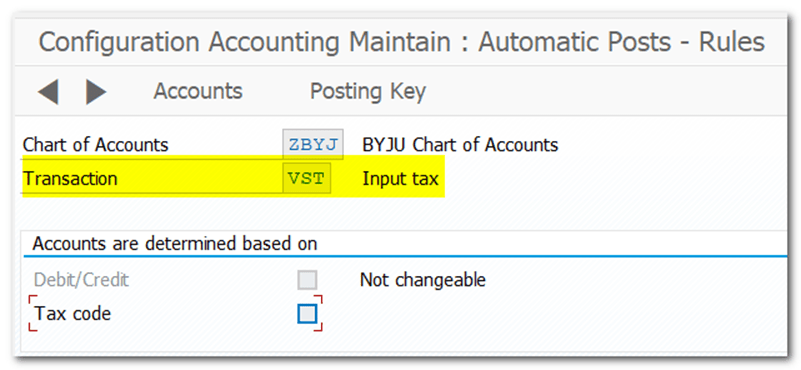

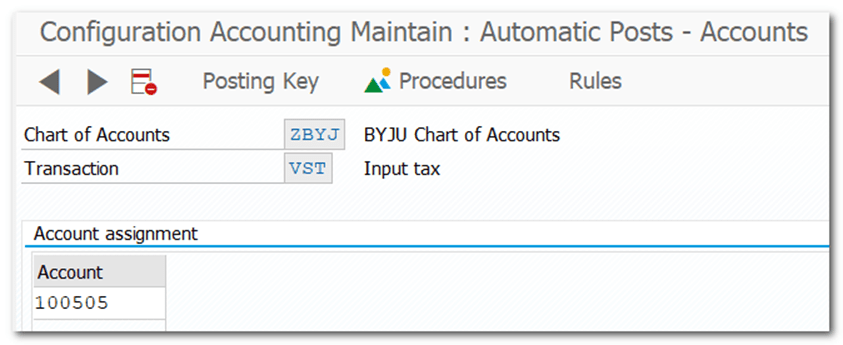

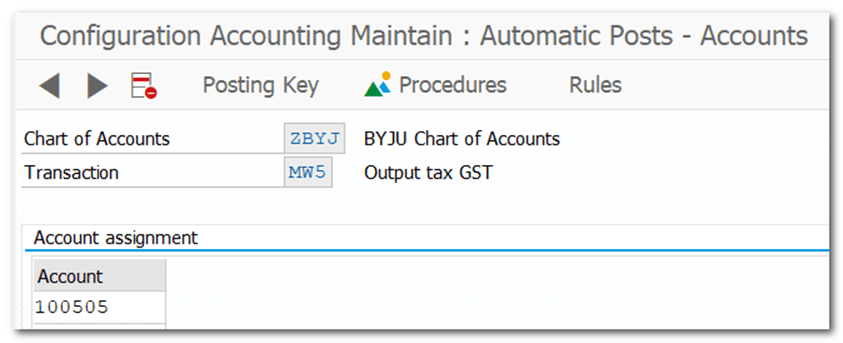

| Step 38 | Assignment of Account for Automatic Posting |

| TCODE | OB40 |

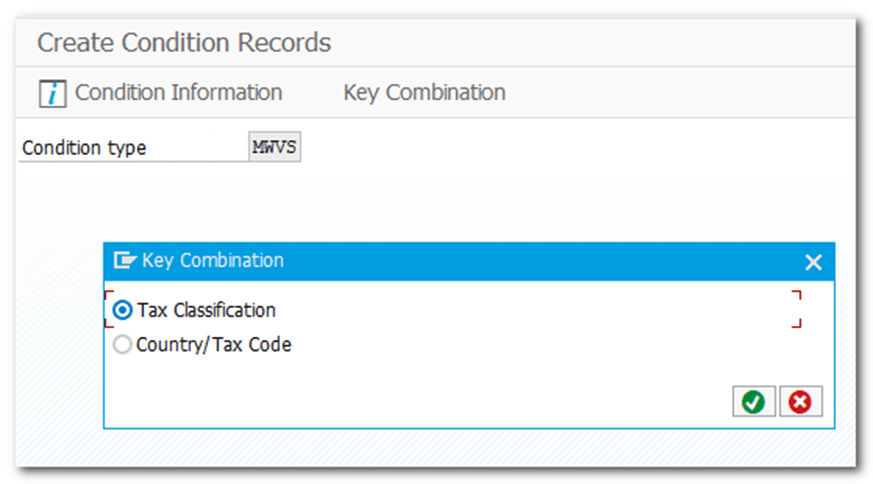

| Step 39 | Maintain Condition records |

| TCODE | FV11 |

OBCN

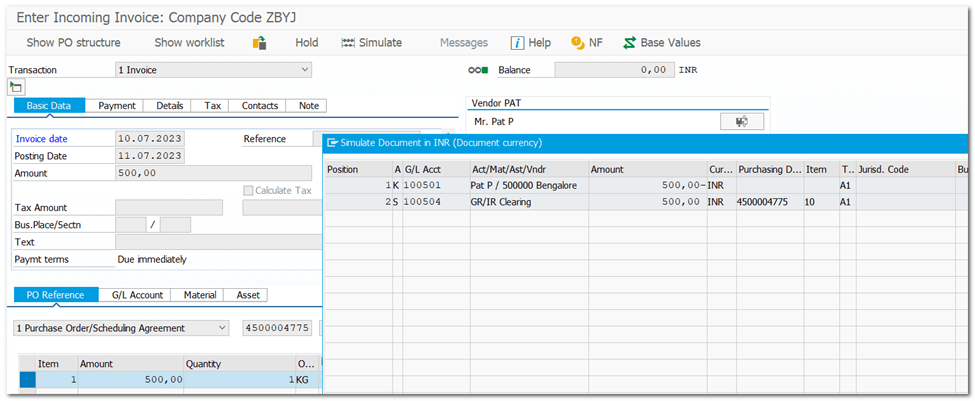

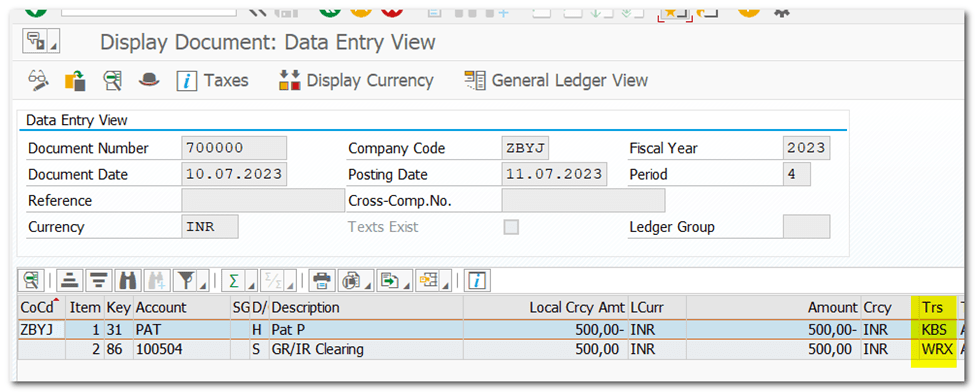

| Step 40 | Invoice Verification |

| TCODE | MIRO |

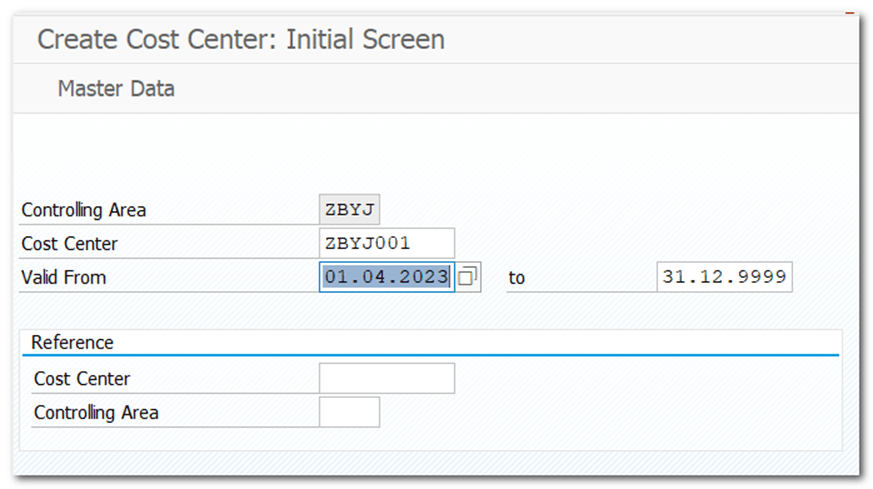

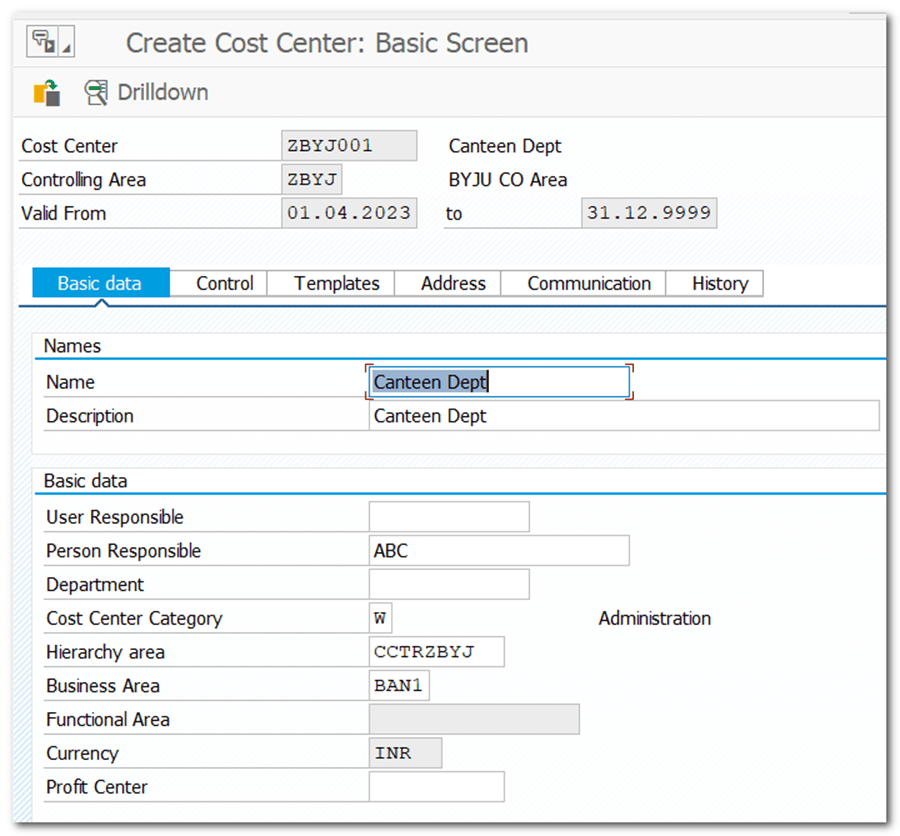

| Step 41 | Creation of Cost Center |

| TCODE | KS01 |

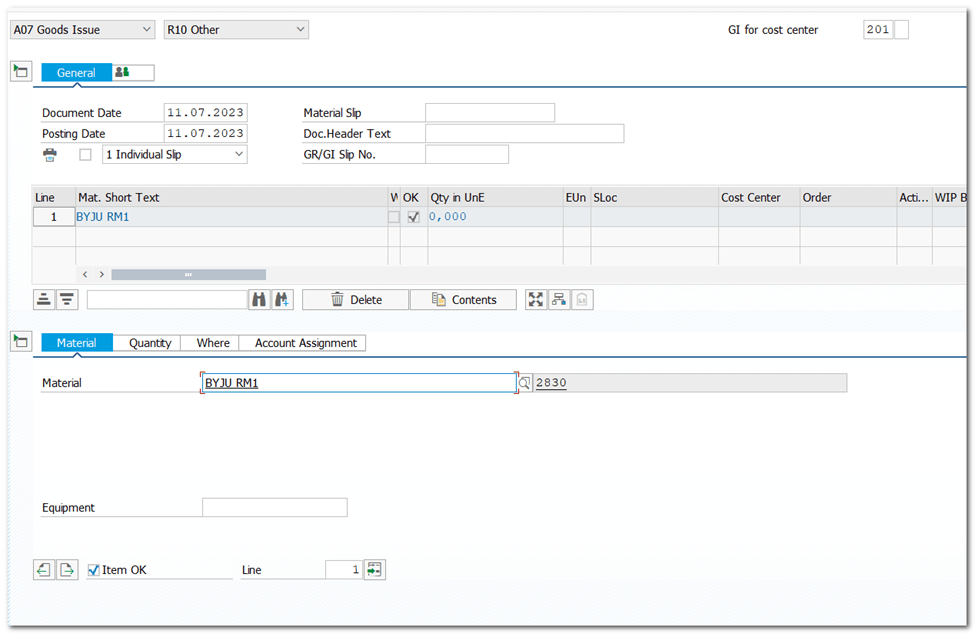

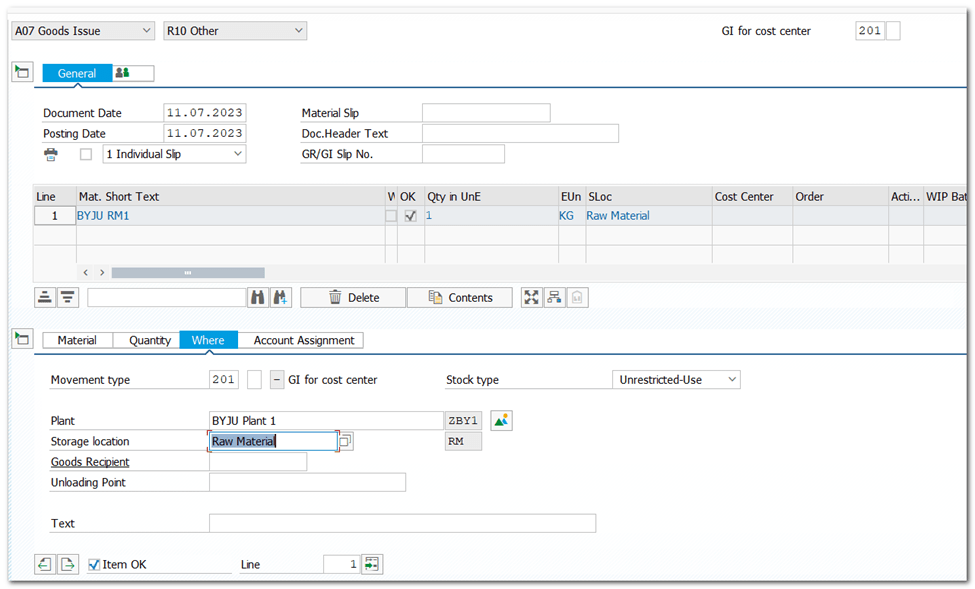

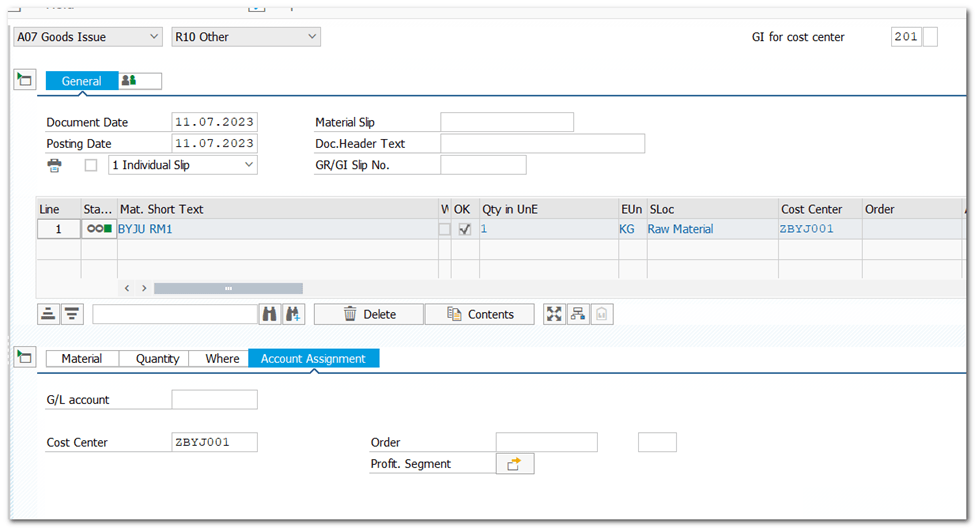

| Step 42 | Goods Issue to Cost Center |

| TCODE | MIGO |

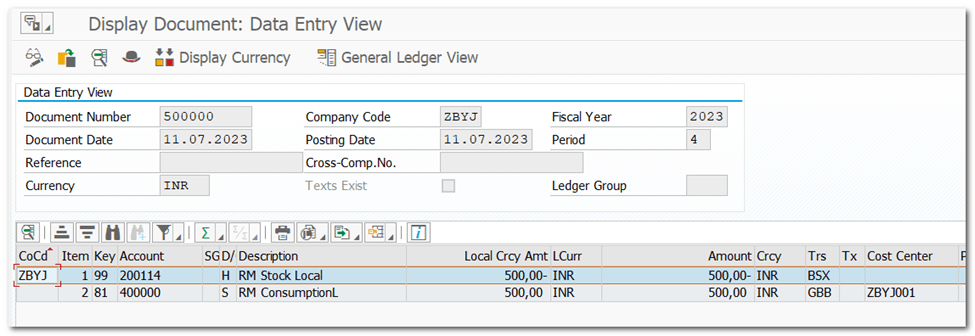

Accounting Doc

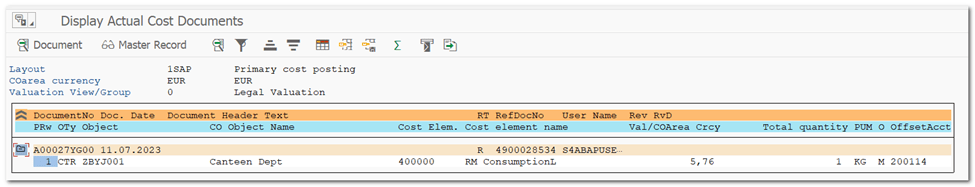

Controlling Doc

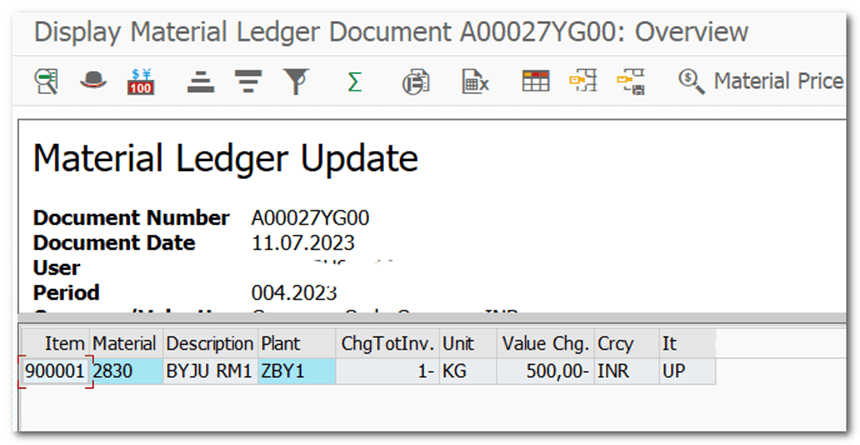

Material Ledger

Material Valuation Data update