LOSC is a storage process used to carry out movement of goods through multiple points based on the physical layout and constraints of the warehouse.

Layout-oriented storage control can only be used with handling units

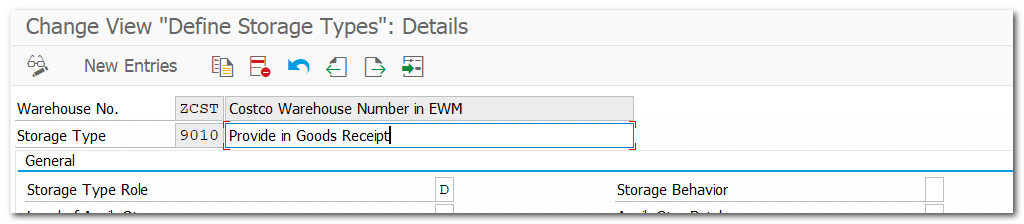

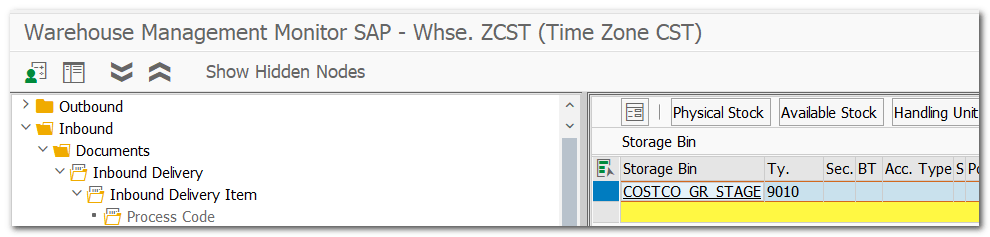

| Step 1. | Define Source Storage Type for GR (9010) |

| IMG | SCW-EWM-Master Data-Define Storage Types |

| Step 1.1. | Create Storage BIN for GR Storage Type |

| TCODE | /SCWM/LS01 /SCWM/MON |

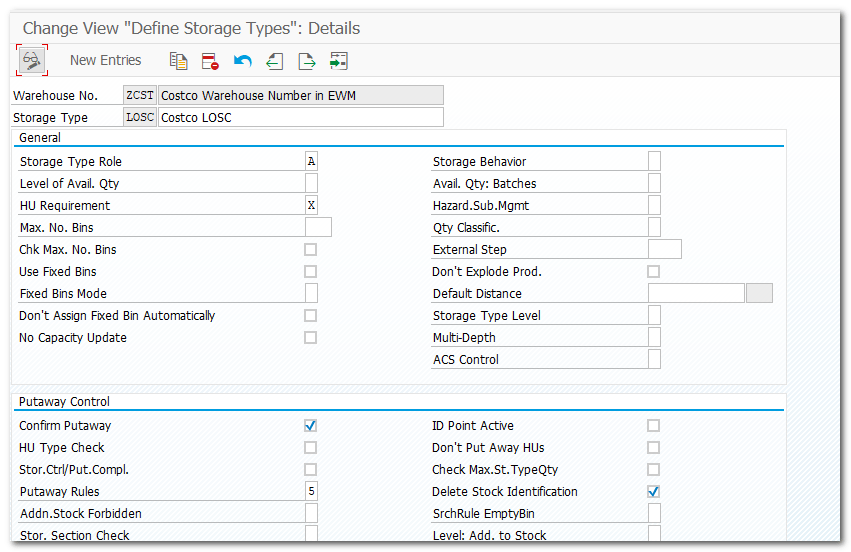

| Step 2. | Define Intermediate Storage Type (LOSC) |

| IMG | SCW-EWM-Master Data-Define Storage Types |

| Storage Type Role “A” Identification Point |

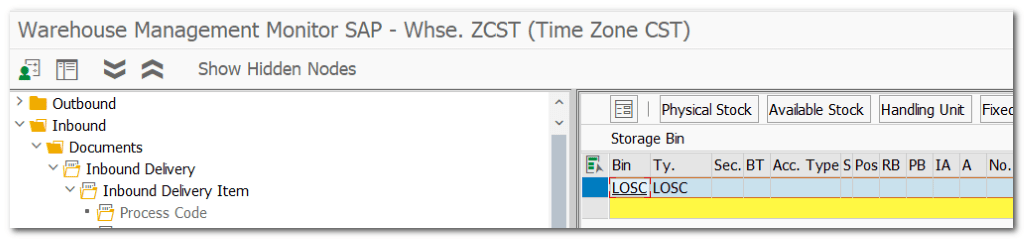

| Step 2.1. | Create Storage BIN for LOSC |

| TCODE | /SCWM/LS01 SCWM/MON |

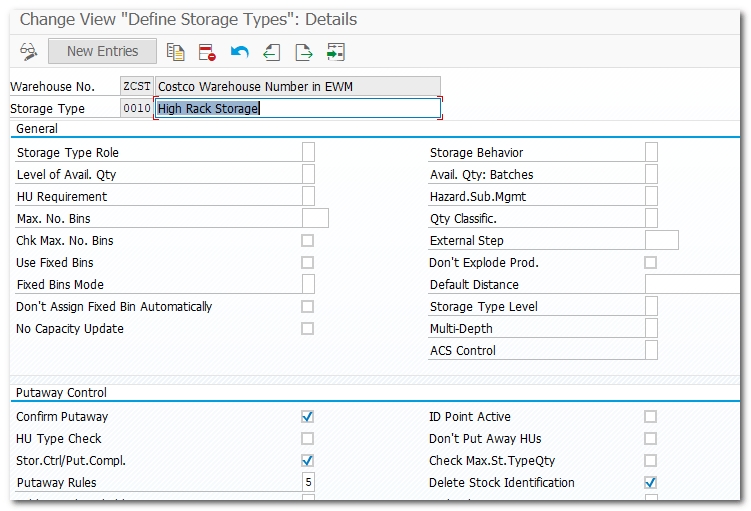

| Step 3 | Define Destination Storage Type for Putaway (0010) |

| IMG | SCW-EWM-Master Data-Define Storage Types |

| Step 3.1. | Create Storage BIN for Putaway Storage Type |

| TCODE | /SCWM/LS01 /SCWM/MON |

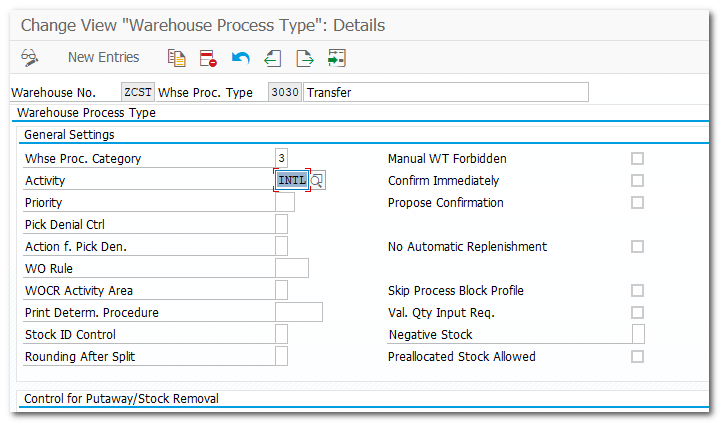

| Step 4. | Define Warehouse Process Type (3030) |

| IMG | SCW-EWM-Cross-Process Settings-Warehouse Task-Define Warehouse Process Type |

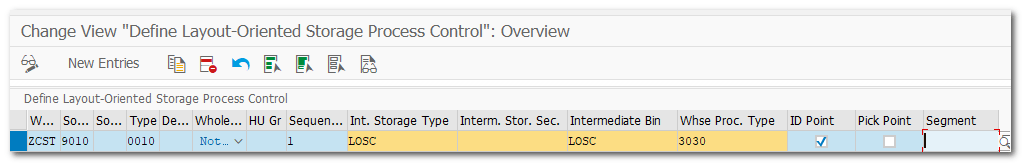

| Step 5. | Define Layout-Oriented Storage Process Control |

| IMG | SCW-EWM-Cross-Process Settings-Warehouse Task-Define Layout-Oriented Storage Process Control |

| Source Storage Type (9010) Destination Storage Type (0010) Intermediate Storage Type (LOSC) Intermediate BIN (LOSC ) Wharehouse Process Type (3030) ID Point for Inbound or Pick Point for Outbound |

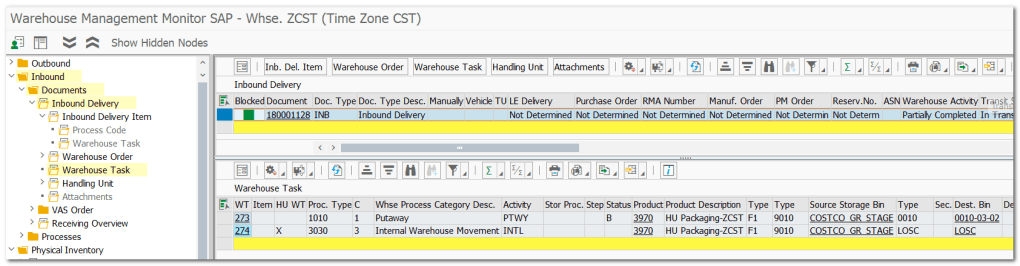

| Step 6. | Test LOSC scenario |

| ME21N VL31N /SCWM/PRDI | Created PO Created Inbound Delivery Inbound Delivery replicated to EWM Create Warehouse Task for WPT 1010 |

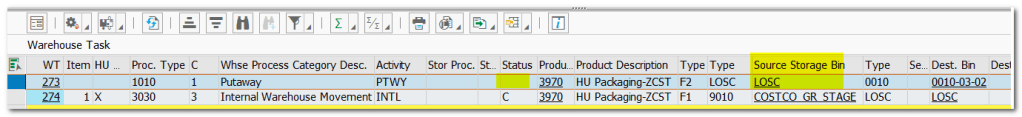

Select and confirm WT #274, subsequent WT will open. Source Storage Type will change from GR to LOSC.

Confirm WT #273 for Final Putaway

Status updated to “C” and HU moved to final BIN