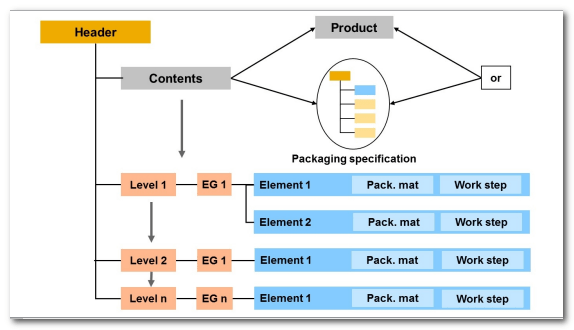

Packaging Specifications are used to specify instructions for packing a material in EWM.

- Packing materials required to pack

- Packing levels needed to store a product

- Product quantities needed to pack various levels

Example, A product may require 6 pieces to be packed in one carton, and then 6 such cartons to be packed into one pallet/bigger carton.

Packaging Specification Structure

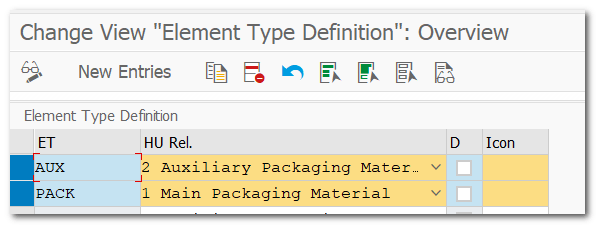

| Step 1. | Define Element Type |

| IMG | SCM Extended Warehouse Management-EWM-Master Data-Packaging Specification-Maintain Structure of Packaging Specification-Define Element Type |

| AUX PACK |

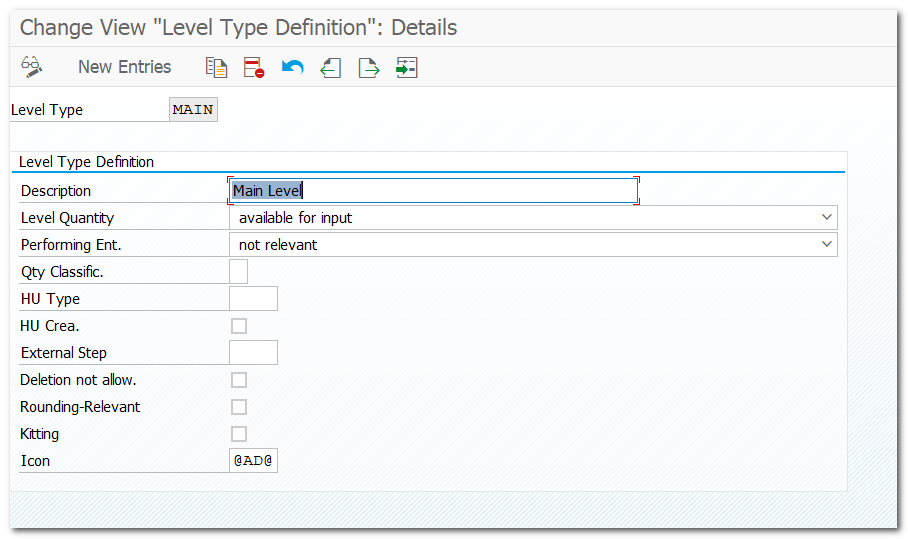

| Step 2. | Define Level Type |

| IMG | SCM Extended Warehouse Management-EWM-Master Data-Packaging Specification-Maintain Structure of Packaging Specification-Define Level Type |

| Main |

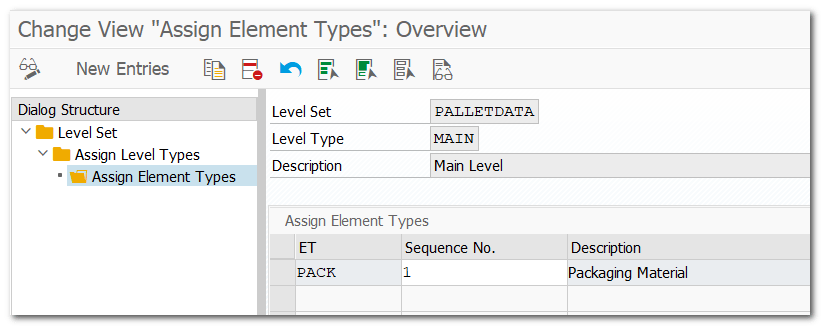

| Step 3. | Level Set |

| Pre-req | An element type is a prerequisite for a level set. A level type is a prerequisite for a level set. |

| IMG | SCM Extended Warehouse Management-EWM-Master Data-Packaging Specification-Maintain Structure of Packaging Specification-Define Level Set |

| (PALLETDATA) |

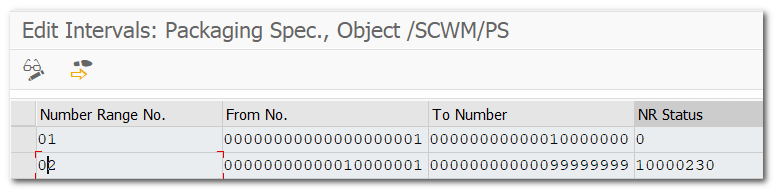

| Step 4. | Define Number Range for Packaging Specification |

| IMG | SCM Extended Warehouse Management-EWM-Master Data-Packaging Specification |

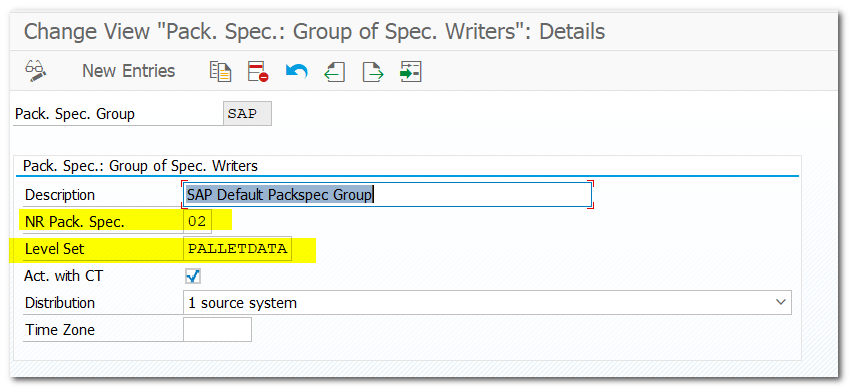

| Step 5. | Define Packaging Specification Group (SAP) |

| Pre-req | Level Set Number Range |

| IMG | SCM Extended Warehouse Management-EWM-Master Data-Packaging Specification-Define Packaging Specification Group |

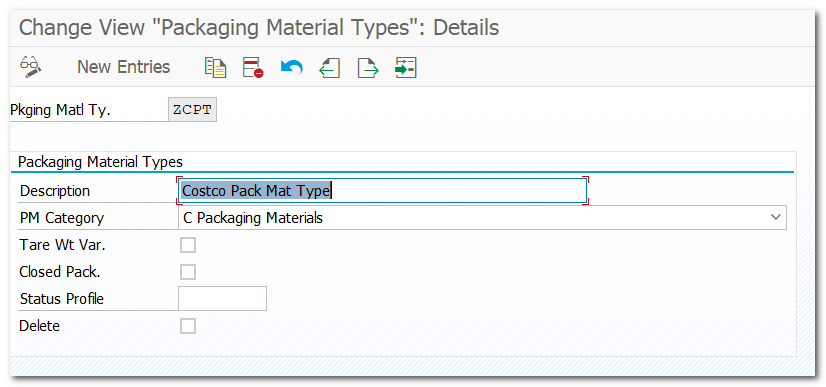

| Step 6. | Define Packaging Material Type (ZCPT) |

| IMG | SCM Extended Warehouse Management-EWM-Master Data-Packaging Specification-Maintain Structure of Packaging Specification-Define Packaging Material Type |

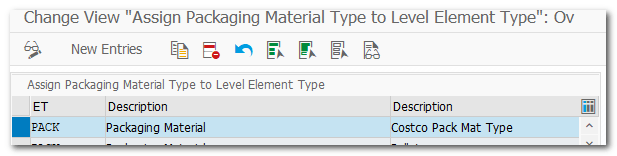

| Step 6.1. | Assign Packaging Material Type to Element Type (PACK-ZCPT) |

| IMG | SCM Extended Warehouse Management-EWM-Master Data-Packaging Specification-Maintain Structure of Packaging Specification-Assign Packaging Material Type to Element Type |

| Step 6.2. | Assign Packaging Material Type to Material/Product Master |

| Reference | https://wetechideas.com/2022/12/03/handling-unit/ |

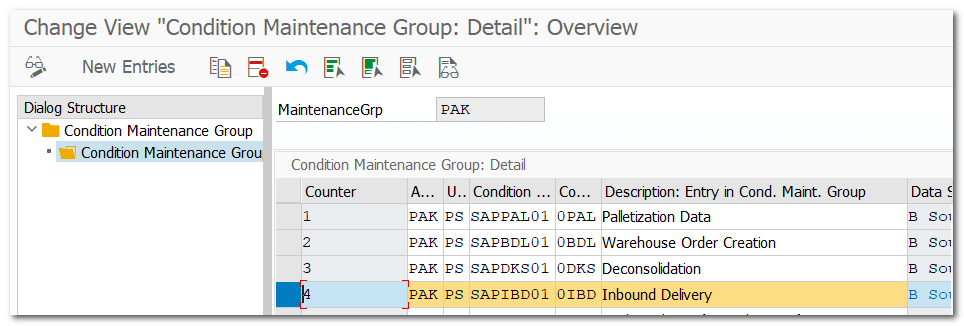

| Step 7. | Determination of Packaging Specifications (Condition Technique) |

| FLOW | Inbound Delivery->Product->Packaging Specification Number->Condition Record Procedure 0IBD->Condition Type 0IBD->Access Sequence 0IBD->Table SAPIBD03(Product) |

| IMG | SCM Extended Warehouse Management-EWM-Master Data-Packaging Specification-Determination of Packaging Specifications Create Condition Maintenance Group |

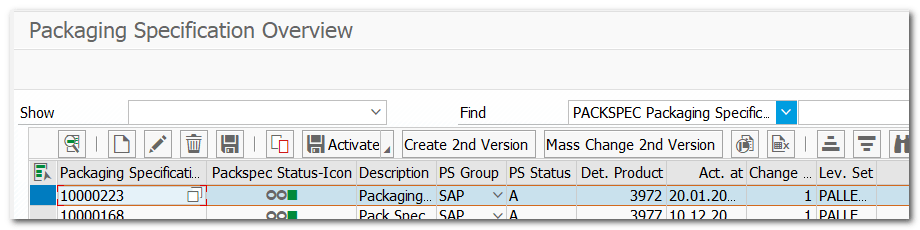

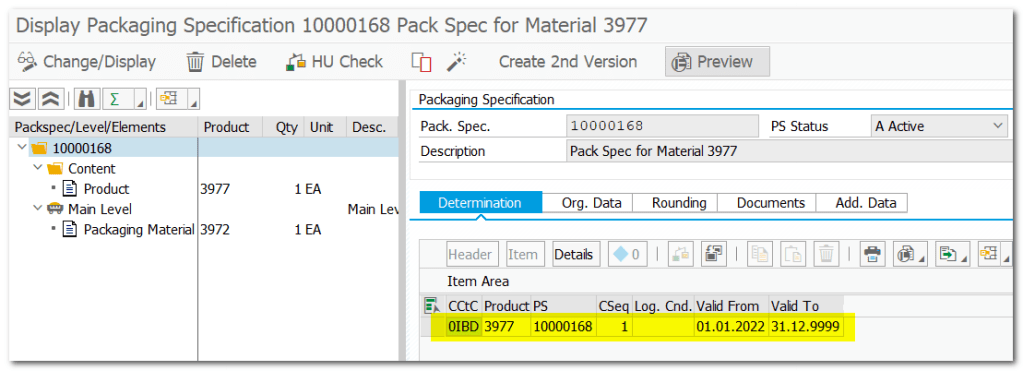

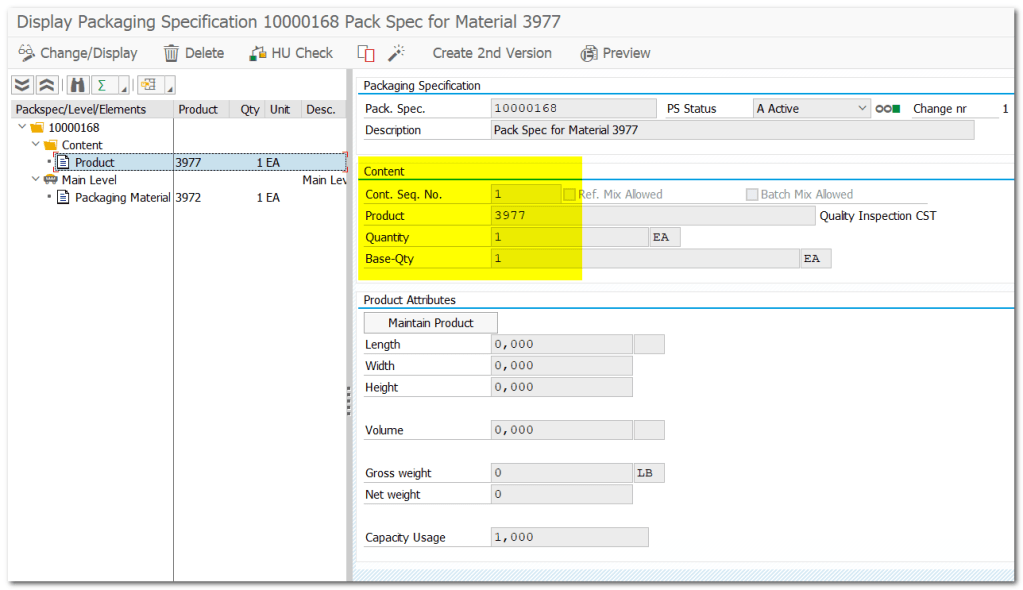

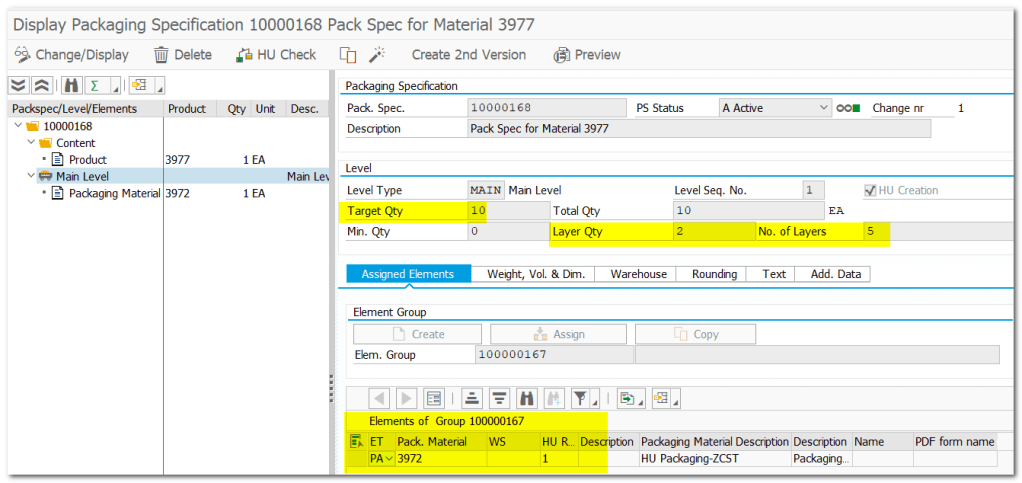

| Step 8. | Maintain Package Specification |

| TCODE | /SCWM/PACKSPEC |

| Usage – PS Condition Type – 0IBD Table – SAPIBD03 Product |

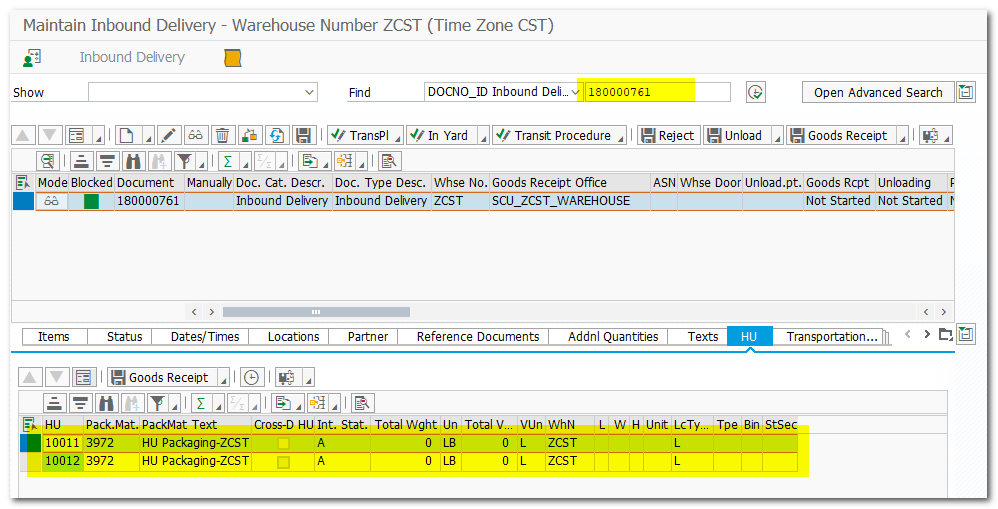

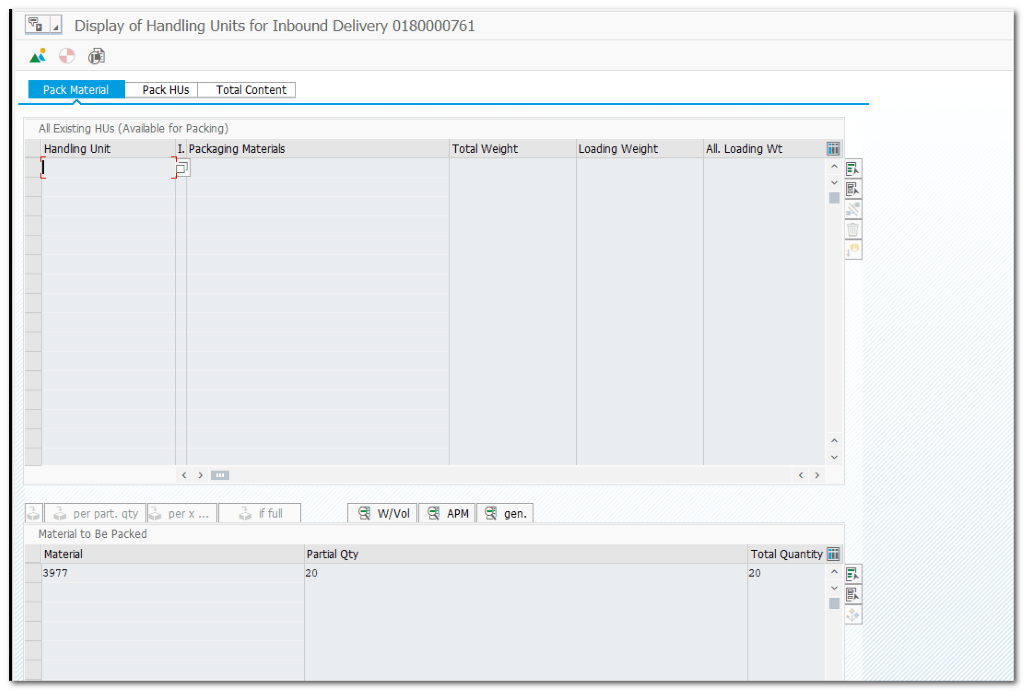

| Test Scenario | HU will generate in EWM as per Packaging Spec |

| ME21N VL31N /SCWM/PRDI | Created PO Created Inbound Delivery without Pack Inbound Delivery Replicated to EWM, HU got generated as per spec |

HU not created in S/4HANA

HU Created in S/4HANA EWM based on Pack Spec