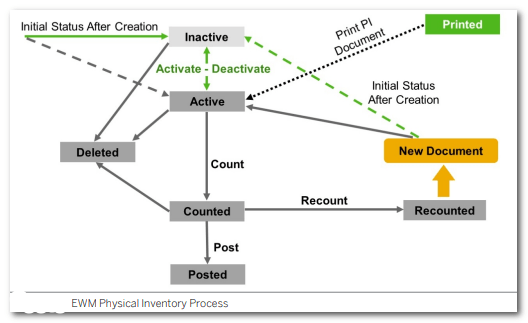

- Physical inventory process in warehouse process keeps count of physical stock.

- Physical inventory helps maintain stock balance in the warehouse and manage balance sheet correctly

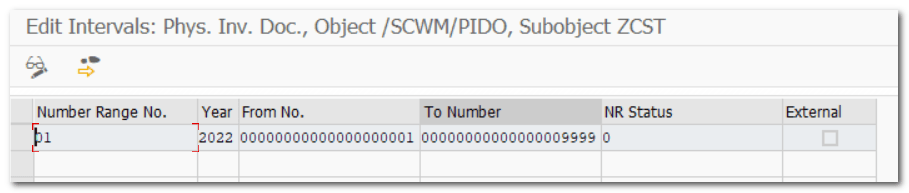

| Step 1. | Define Number Range for Physical Inventory Documents |

| IMG | SCM Extended Warehouse Management- EWM-Internal Warehouse Processes-Physical Inventory-Warehouse-Number-Specific Settings |

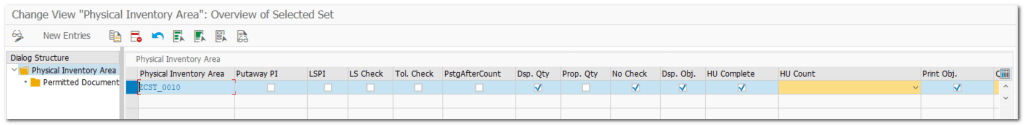

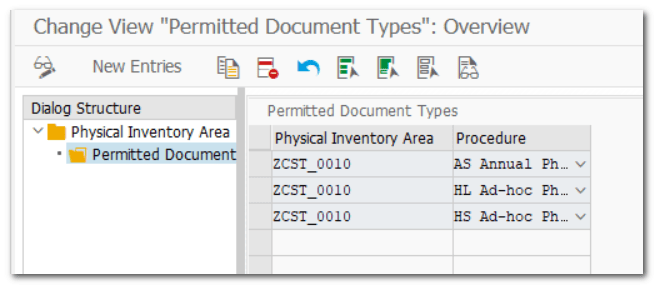

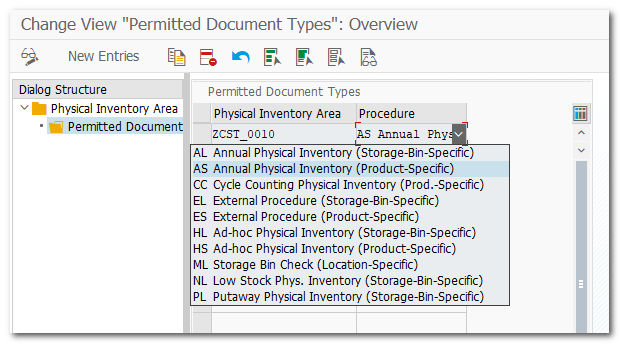

| Step 2. | Define Physical Inventory Area |

| IMG | SCM Extended Warehouse Management- EWM-Internal Warehouse Processes-Physical Inventory-Physical-Inventory-Area-Specific Settings |

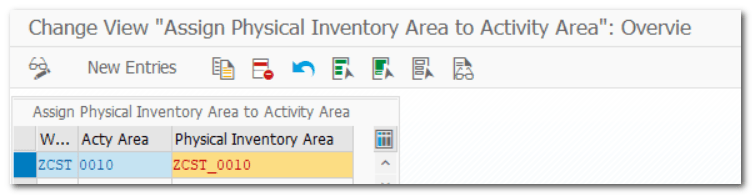

| Step 2.1. | Assign Physical Inventory Area to Activity Area |

| IMG | SCM Extended Warehouse Management- EWM-Internal Warehouse Processes-Physical Inventory-Warehouse-Number-Specific Settings |

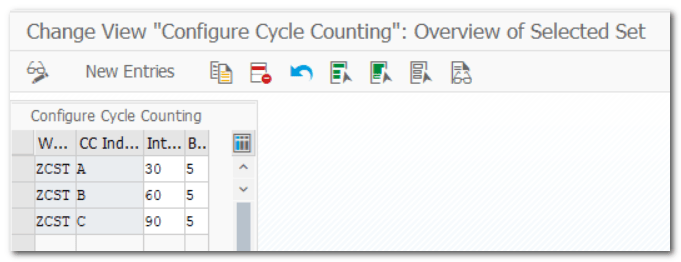

| Step 3. | Configure Cycle Counting |

| IMG | SCM Extended Warehouse Management- EWM-Internal Warehouse Processes-Physical Inventory-Warehouse-Number-Specific Settings |

Example

Configure cycle counting indicator A to have an interval of 30 working days between each cycle count and a buffer of 5 working day.

This means that products in your warehouse using cycle counting indicator A should be counted every 30-36 working days

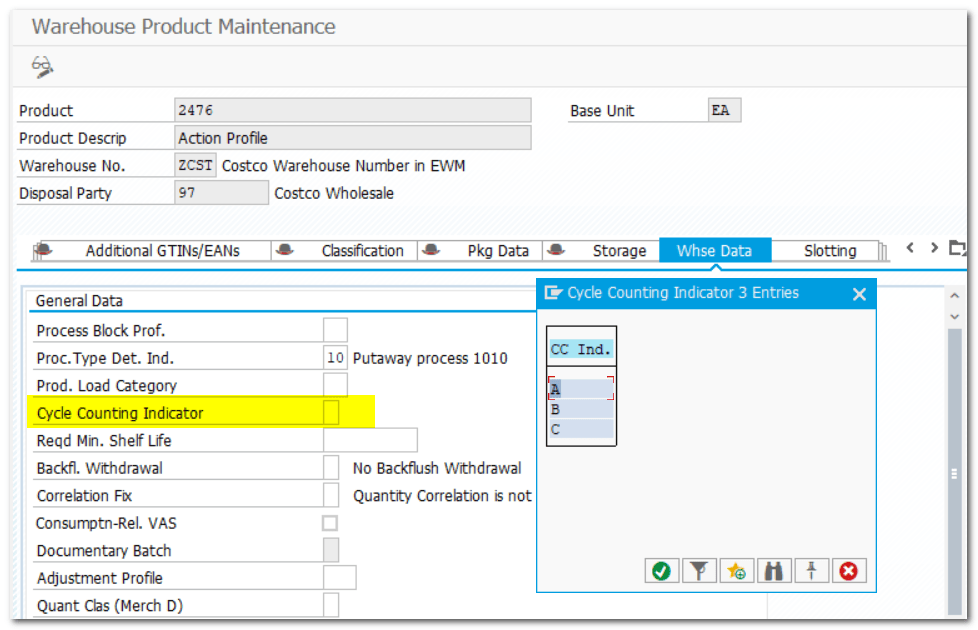

| Step 3.1. | Master Data Maintenance |

| TOCDE | SCWM/MAT1 |

| Step 3.2. | Create Physical Inventory Document (Cycle Counting) |

| TOCDE | /SCWM/PI_CC_CREATE |

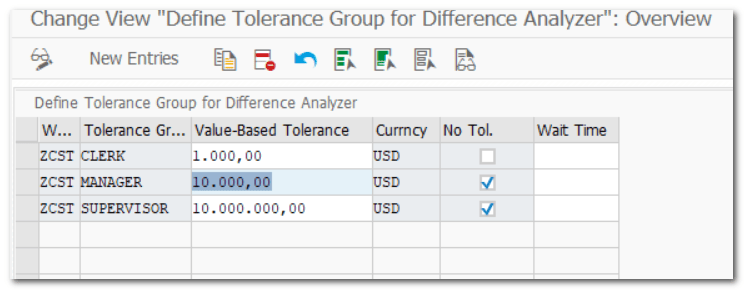

| Step 4. | Define Tolerance Group for Difference Analyzer |

| IMG | SCM Extended Warehouse Management- EWM-Internal Warehouse Processes-Physical Inventory-Warehouse-Number-Specific Settings-Define Tolerance Groups- |

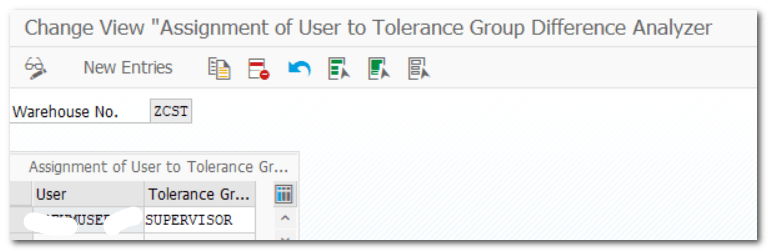

| Step 4.1. | Assign Users to Tol. Group for Diff. |

| TCODE | /SCWM/PI_USER_DIFF |

| Step 5. | Define Tolerance Group for Posting Differences (EWM level) |

| IMG | SCM Extended Warehouse Management- EWM-Internal Warehouse Processes-Physical Inventory-Warehouse-Number-Specific Settings-Define Tolerance Groups- |

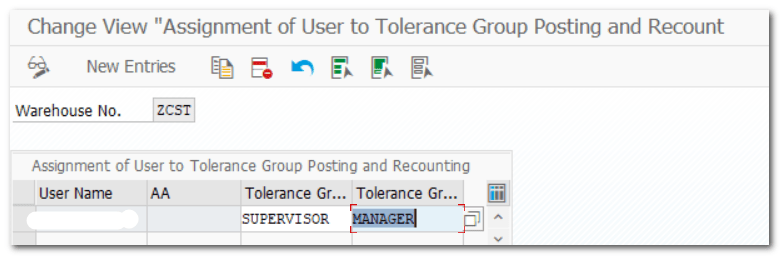

| Step 5.1. | User Maint. Tolerance Gr. Phys.Inv. |

| TCODE | /SCWM/PI_USER |

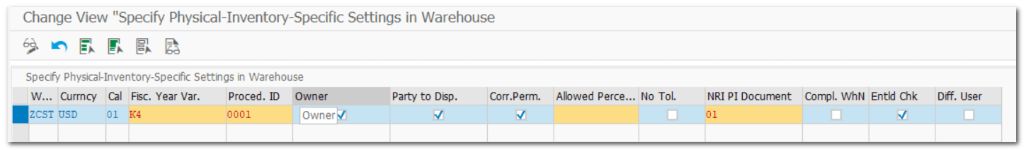

| Step 6. | Specify Physical-Inventory-Specific Settings in the Warehouse |

| IMG | SCM Extended Warehouse Management- EWM-Internal Warehouse Processes-Physical Inventory-Warehouse-Number-Specific Settings Example, Assign Fiscal Year Variant |

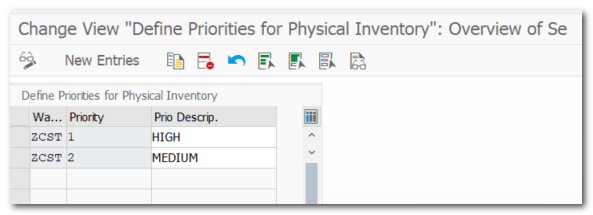

| Step 7. | Define Priorities |

| IMG | SCM Extended Warehouse Management- EWM-Internal Warehouse Processes-Physical Inventory-Warehouse-Number-Specific Settings-Reason and Priority |

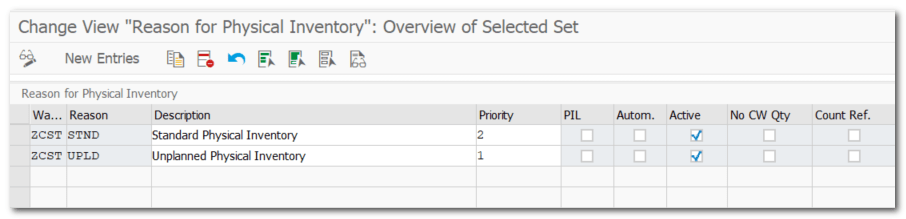

| Step 7.1. | Define Reason for Physical Inventory |

| IMG | SCM Extended Warehouse Management- EWM-Internal Warehouse Processes-Physical Inventory-Warehouse-Number-Specific Settings-Reason and Priority |

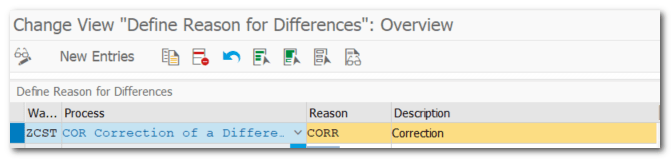

| Step 8. | Define Reason for Differences |

| IMG | SCM Extended Warehouse Management- EWM-Internal Warehouse Processes-Physical Inventory-Warehouse-Number-Specific Settings-Reason and Priority |

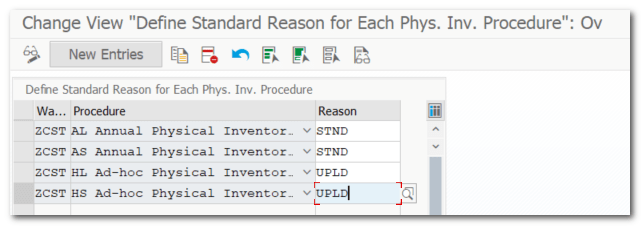

| Step 9. | Define Standard Reason for Each Phys. Inv. Procedure |

| IMG | SCM Extended Warehouse Management- EWM-Internal Warehouse Processes-Physical Inventory-Warehouse-Number-Specific Settings-Reason and Priority |

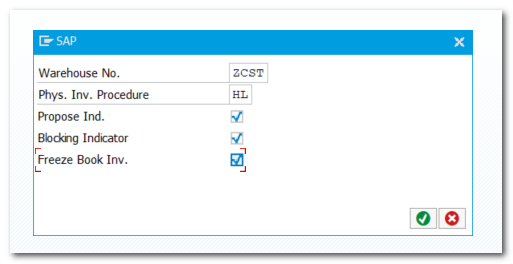

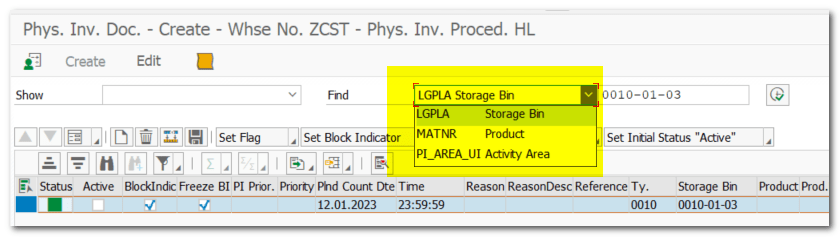

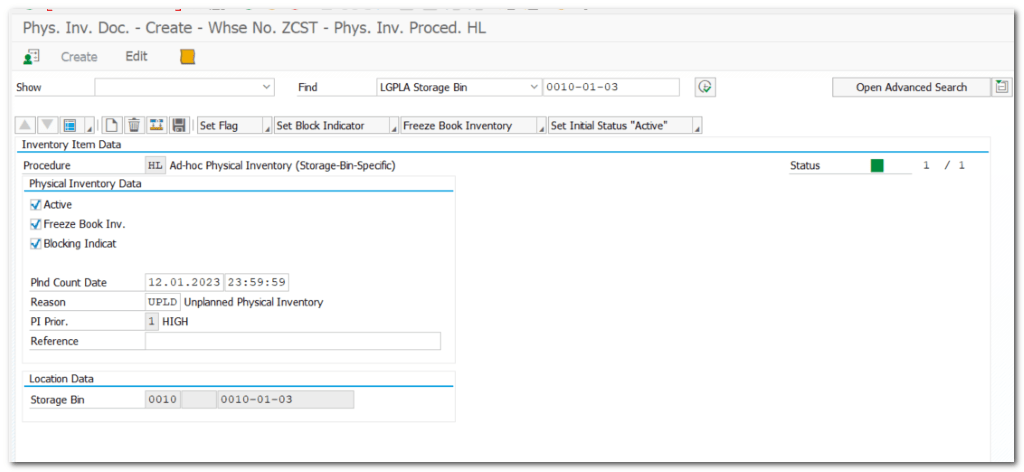

| Step 10. | Test Scenario: Create Physical Inventory Document |

| TCODE | /SCWM/PI_CREATE Logistics-SCM Extended Warehouse Management- EWM-Physical Inventory |

Note: Physical Inventory @ Activity Area, Storage Bin, Product

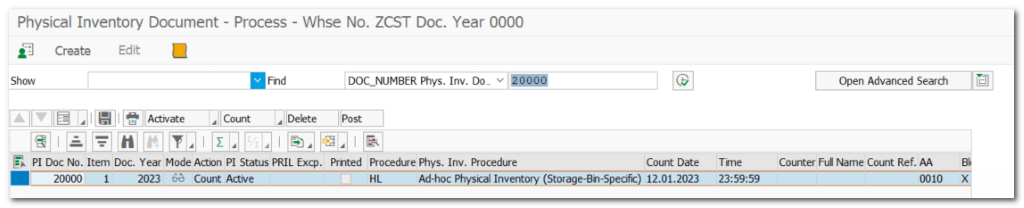

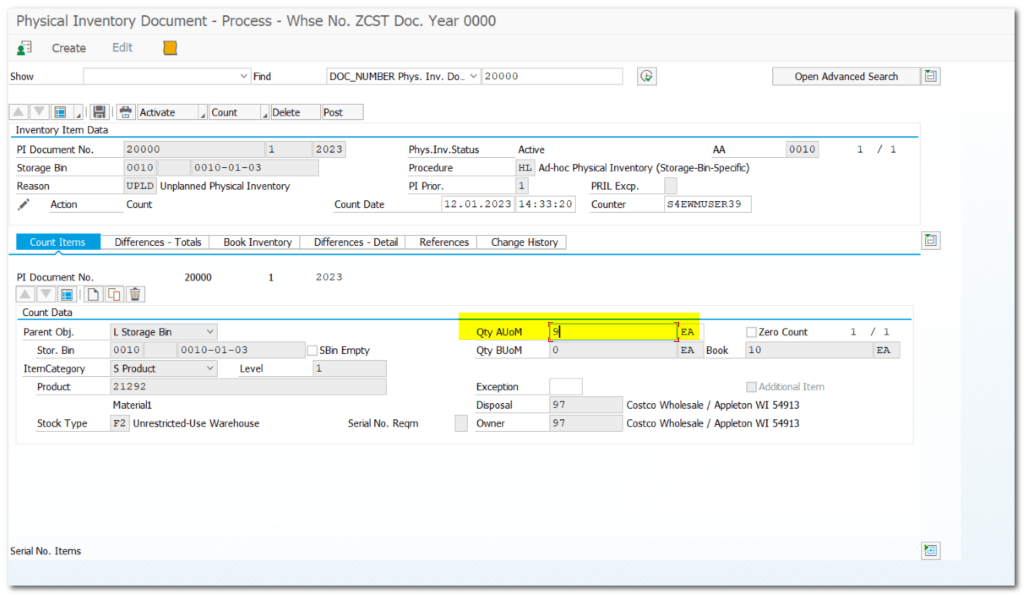

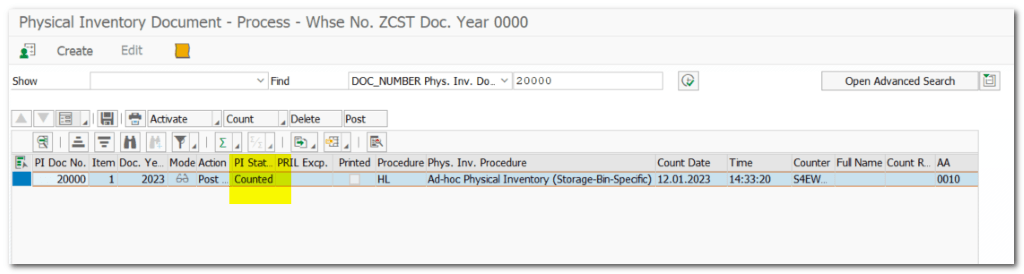

| Step 10.1. | Process Physical Inventory Document |

| TCODE | /SCWM/PI_PROCESS Logistics-SCM Extended Warehouse Management- EWM-Physical Inventory Click on Count |

Status updated to Counted

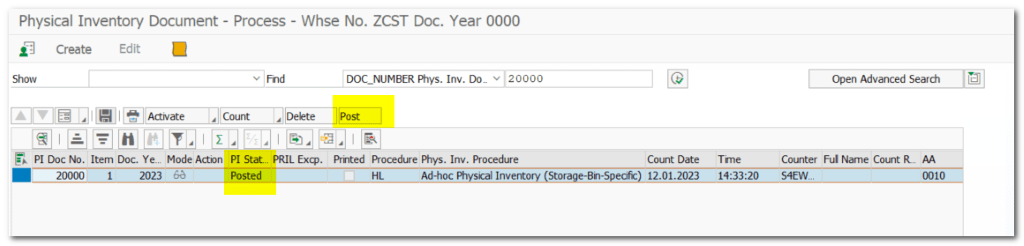

Click on Post

| Step 10.2. | Difference Analyzer (EWM will update difference to IM ) |

| TCODE | /SCWM/DIFF_ANALYZER Logistics-SCM Extended Warehouse Management- EWM-Physical Inventory Click on Post |

Post difference

| Step 10.3. | Check Material Document in S/4HANA(IM) |

| TCODE | MB51 |